Oracle Inventory

• Defining part numbers

• Modeling organization structures

• Tracking perpetual inventory

• Maintaining accurate on-hand balances

• Planning material replenishments

• Forecasting anticipated demand

You must plan how Oracle Inventory represents your company’s inventory sites and business units. This includes defining organizations, locations, subinventories, and locators depending on your company structure. You also must plan how to implement certain parameters and what level of the structure controls them.

Multi-org often refers to an Oracle Applications setup used to enable multiple business units in a single install. With multi-org, a business enterprise may set up multiple business units with differing sets of books, operating units, and legal entities all within a single instance. With multi-org, goods my be sold out of one operating unit or legal entity and shipped out of another, and the system will process an intercompany sale to properly account for it.

Multi-org, however, should not be mistaken for installs with multiple inventory organizations. You do not have to use Oracle Applications multi-org to support multiple inventory organizations if all the inventory organizations share the same set of books, operating unit, and legal entity.

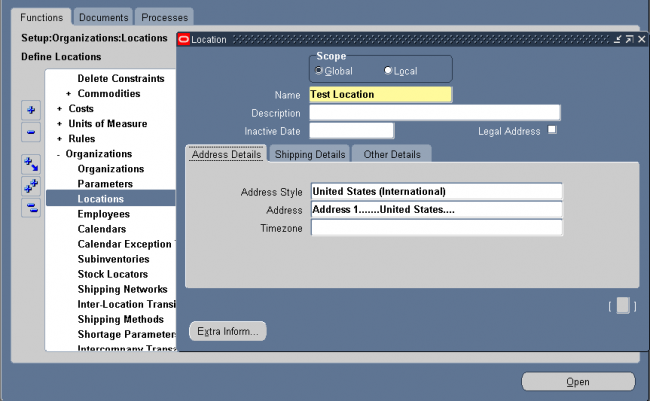

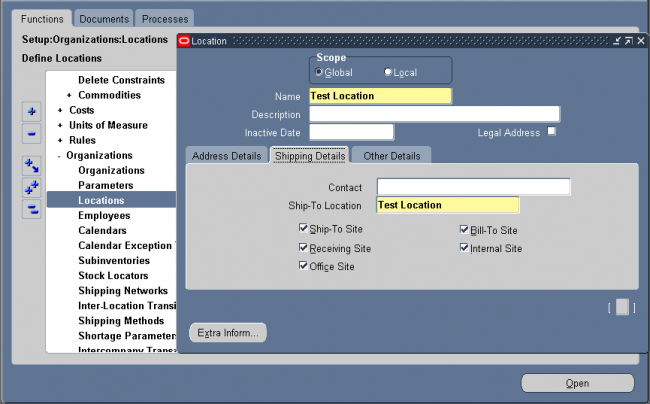

Location: A location is simply a name and address, and is assigned to an organization or used to indicate delivery information on a purchase order. You may define as many locations as you like, but only one location may be assigned to an inventory organization.

Business group is a group of companies that does business in different markets under common administrative or financial control whose members are linked by relations of interpersonal trust on the bases of similar personal ethnic or commercial background a business group.

Set of Books (SOB): The financial entity that represents the chart of accounts, fiscal calendar, and base currency. The SOB is set up in the General Ledger.

Legal Entity Organization: An entity used to represent a legal company. Fiscal and tax reporting are done at the Legal Entity level.

A legal employer is a legal entity that is responsible for employing people in a particular country. Therefore, if you employ people in a country, then you must have at least one organization classified as a legal entity and a legal employer.

The Configuration Workbench classifies an organization as a GRE/Legal Entity where your enterprise operates in a country, and classifies it as an Employer if you employ people in that country also. For example, you can have a legal entity in a country where you do business, but do not employ people in that country.

Operating Unit Organization: A business unit that shares a common Purchasing, Accounts Payable, Order Entry and Accounts Receivable setup. An operating unit may consist of multiple inventory organizations, with multiple manufacturing sites, distribution centers, and sales offices, but they share a common sales order and purchase order system. For example, a sales order may have lines shipping from different inventory organizations or a purchase order may have lines destined for different inventory organizations.

Inventory Organization: An entity used to represent a manufacturing or distribution site. Inventory organizations are where a user tracks on-hand balances, manufactures goods, and transacts the daily ins and outs of material movement. An inventory organization is the lowest level entity for costing goods, planning material requirements, and securing system access. Only a single address may be assigned to an Inventory Organization. An inventory organization is assigned a Set of Books which determines the chart of accounts, fiscal calendar, and base currency for all financial and value added activities that occur within the organization.

Inventory Organizations are also assigned to a Legal Entity Organization and an Operating Unit Organization.

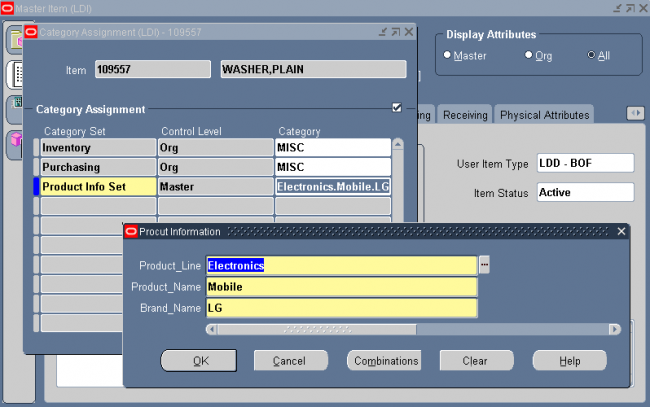

A variation on the inventory organization is the master item organization. Generally, with Oracle Applications a single inventory organization is created and designated at the master organization. Items are defined first in the master organization, then enabled in other inventory organizations as necessary. Some of the item attributes are set as controlled at the master organization and therefore the attribute values cannot be updated within individual inventory organizations. Category sets may also be designated as master organization level. Cross-references are also master level only or master level optional as well.

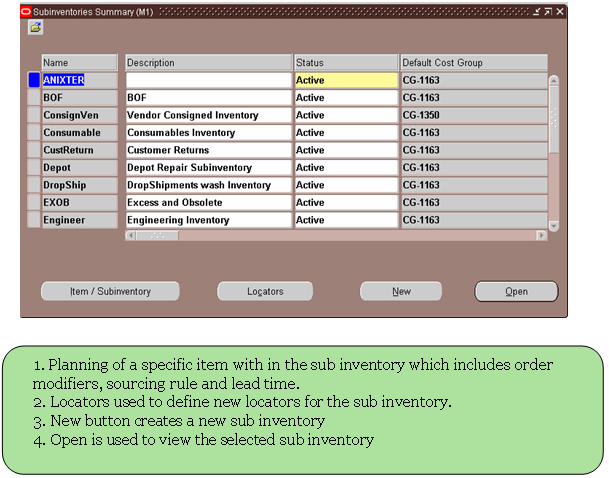

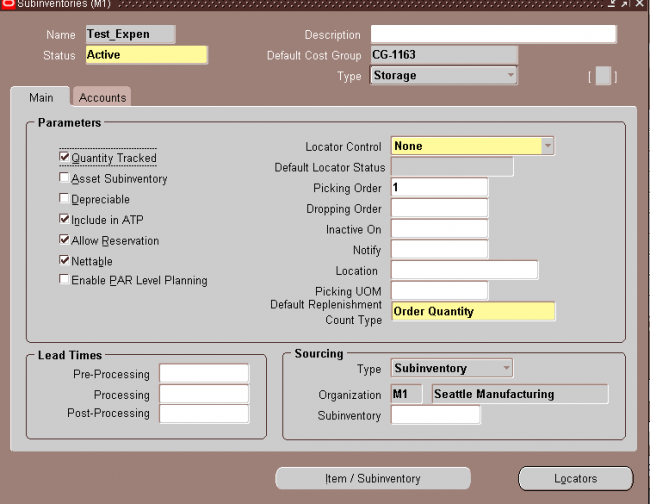

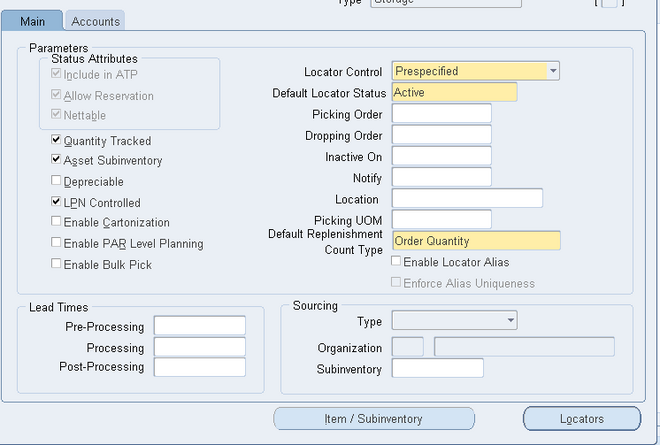

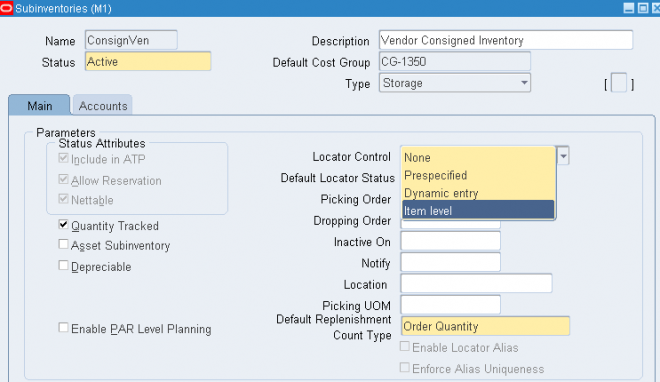

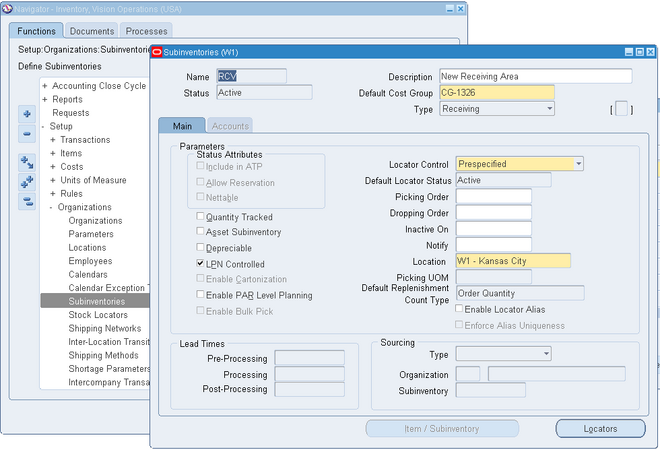

Subinventory: Physical or logical locations for storing inventory. Subinventories are generally defined to represent the main stores area as well as stocking points on the production floor. Additional subinventories may be used to specify supply closets or cabinets and the cage area for discrepant material. Subinventories are flagged as to availability for planning (nettable), reservations, and available to promise checks, thereby determining the availability of the material stored in the subinventory. Subinventories are assigned material asset account numbers. As goods move in and out of a subinventory a transaction posts to the asset account.

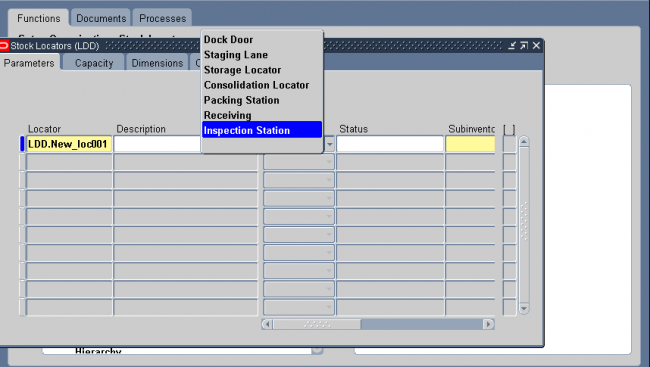

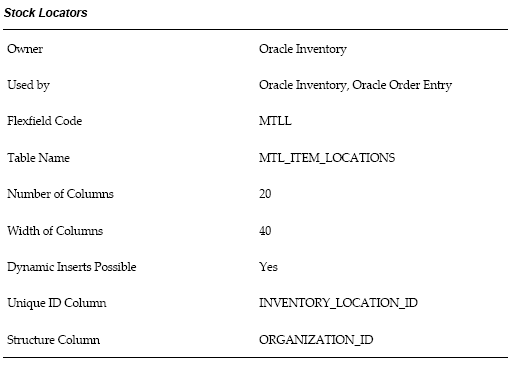

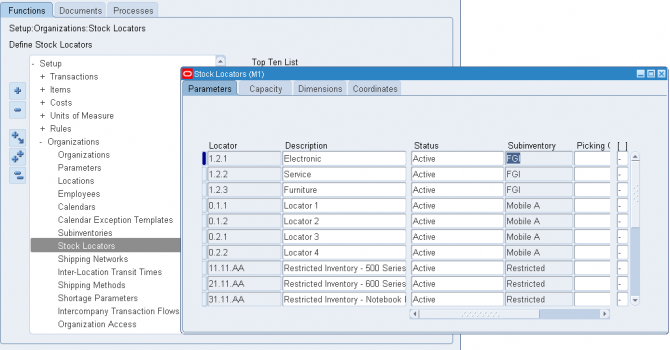

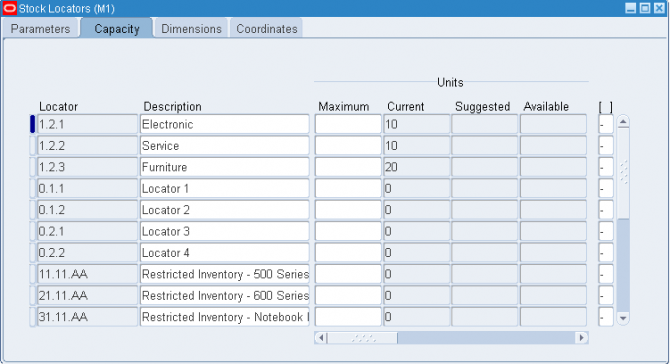

Stock Locator: A physical area within a stockroom. The stock locator is a key flexfield that is often defined as a multiple segment flexfield with the segments representing the physical layout of a stockroom. For example, a stockroom may be laid out in rows of shelves with bins on the shelves, each numbered so that a row/shelf/bin combination would direct someone to a particular material storage compartment. Such an implementation would define a locator flexfield as a 3 segment flexfield with segments for row, shelf, and bin.

Attachment of LE/OU/INV with BG

We never attach any LE/OU/INV with BG in front end...but its available in HR_ALL_ORGANIZATION_UNITS in column Business_Group_ID..so the question is from where it comes?

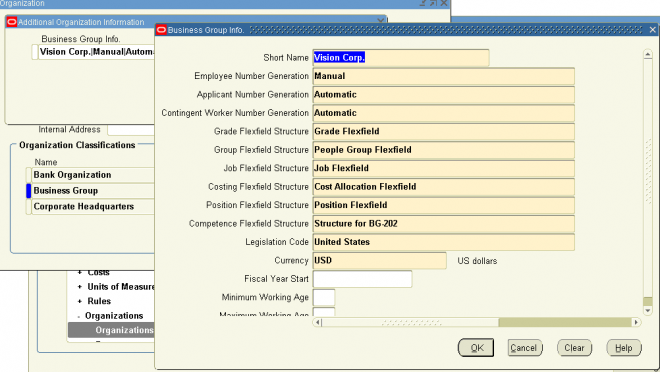

First we create a Business Group. When ever we create a business group the system creates an organization with type businessgroup and attach a business group ID 'N' which is same as the organization ID for that Business group.

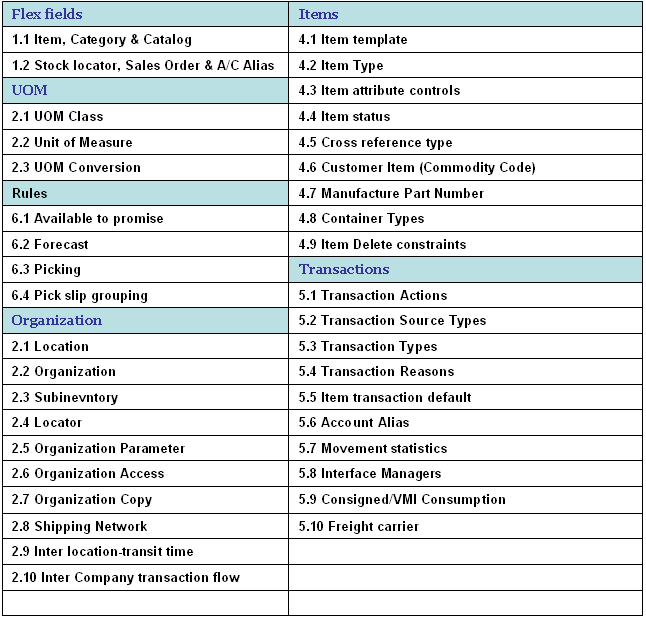

After that we attach the business group to a responsibility through the profile option HR : Business Group.

Next we create whenever we create a new LE/OU/Inv with one responsibility the system 'll attach the Business Group which is attached with the HR : Business group for that particular responsibility.

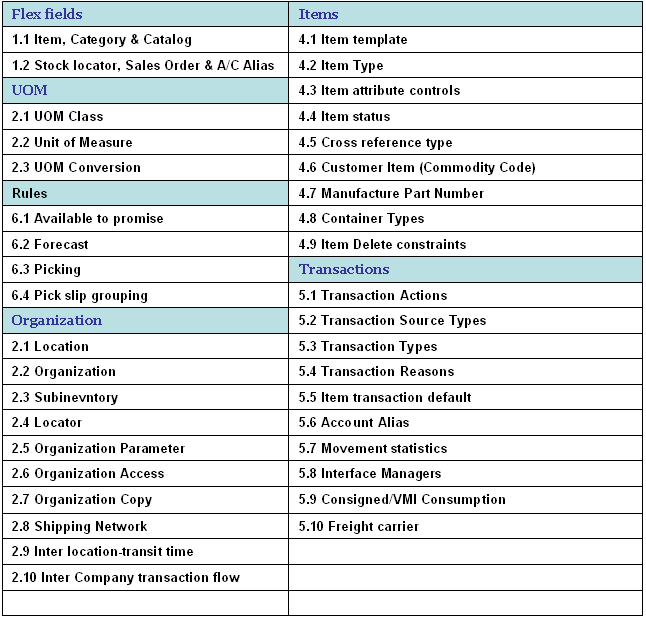

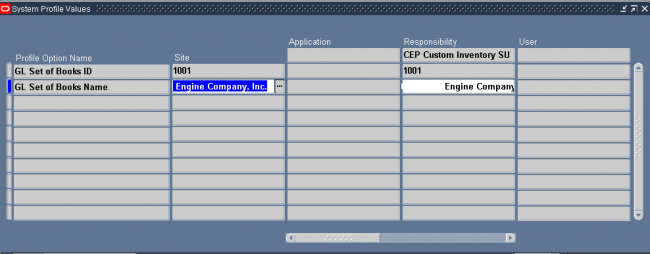

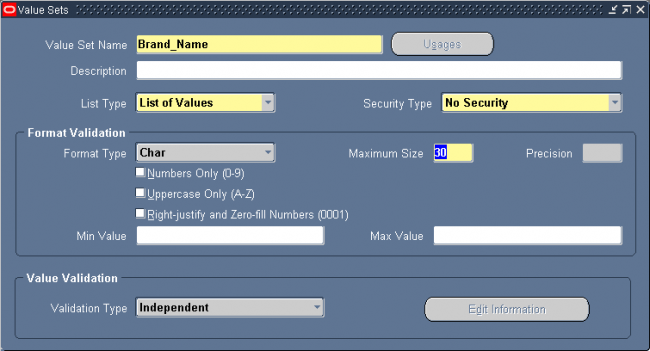

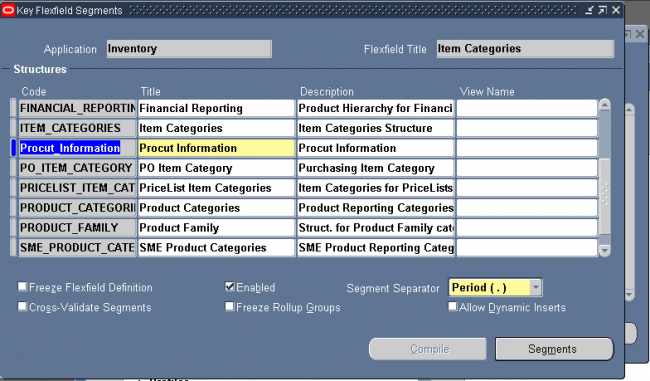

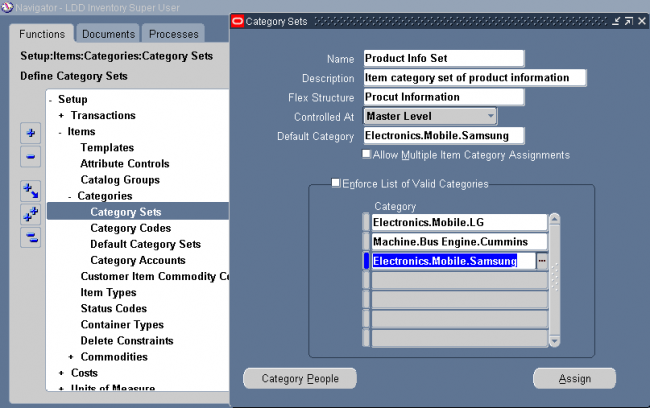

You can define multiple segment structures for the Item Categories Flexfield. Each segment structure may have its own display prompts and fields.

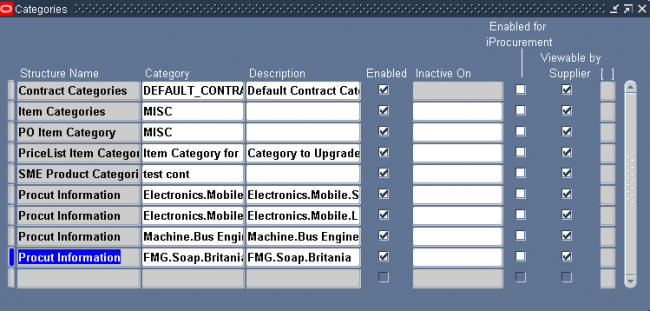

When you install or upgrade Oracle Inventory or Oracle Purchasing, Oracle provides two category flexfield structures by default: Item Categories and PO Item Category.

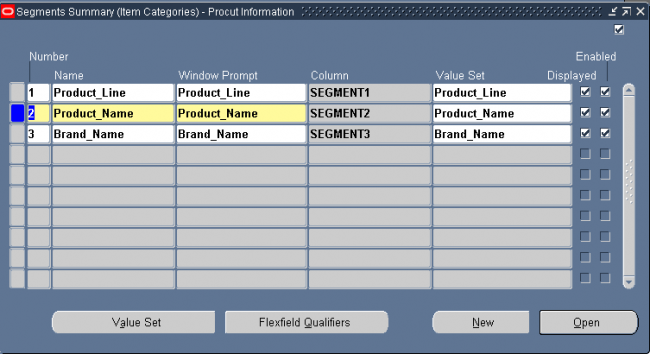

Each segment structure can display prompts and fields that apply specifically to a particular naming convention. For example, you might want one of your category sets to use two segments for the names of categories. Another item grouping scheme might use just one segment for the names of categories. You choose a flexfield structure for every category set and category that you define.

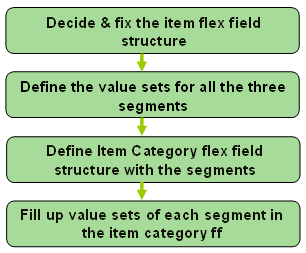

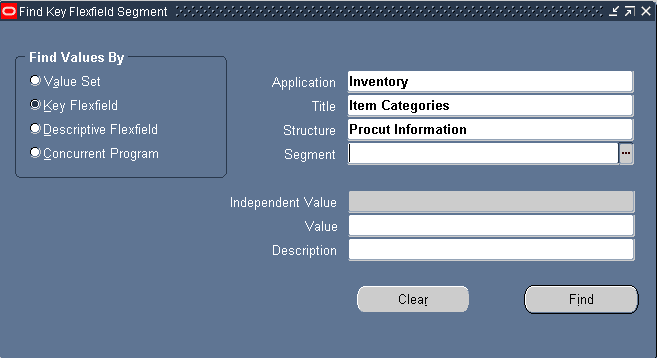

3. Define the item category flex field.

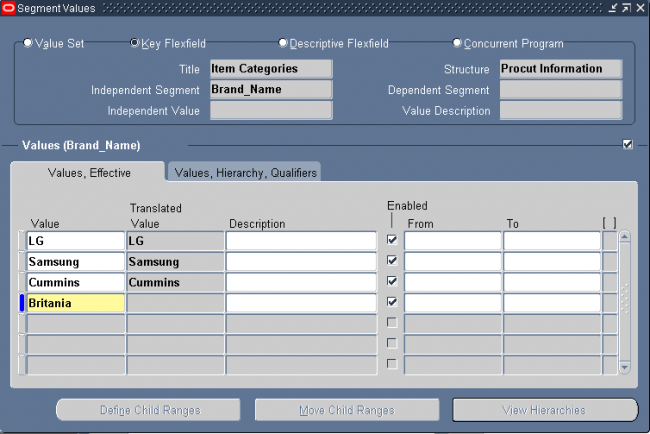

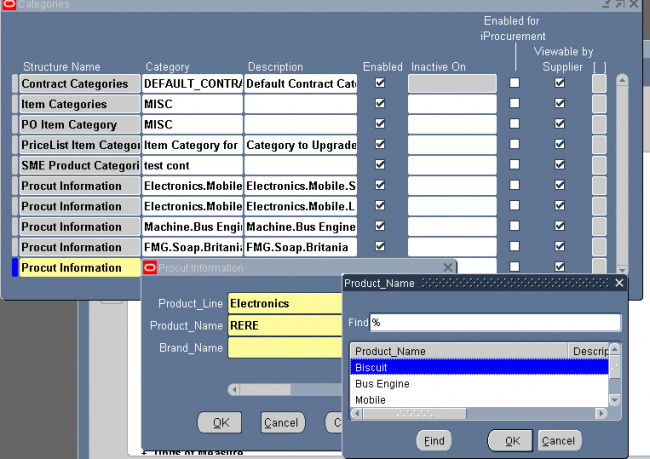

4. Filling up the value set of the stucture product information

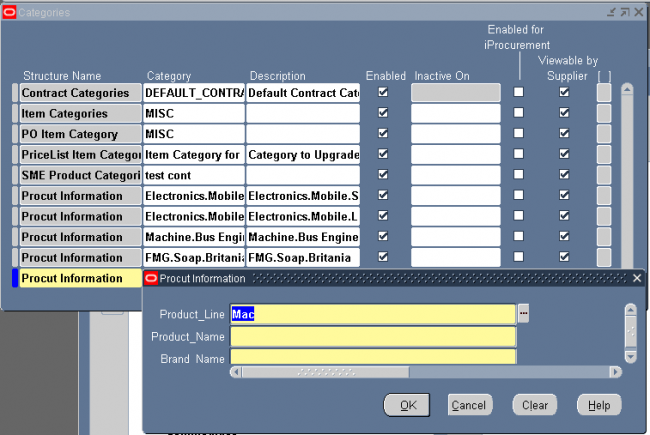

Enter a flexfield Structure Name, a unique Category (value) for each structure segment, and a unique description for the new category. If you want to make a category inactive, enter a date you want the category to be inactive on. Save your work.

If you choose a multi–segment flexfield structure you can assign a specific meaning to each segment. For example in our case the category "Electronics.Mobile.Samsung" means an item assinged to this category is a samusng brand mobile device of elcetroincs product group.

Category sets may be used as a means to develop custom lists of items on which to report and sort. You can also create other category sets such as John’s Priority or Jane’s Priority, with categories like high, medium, and low.

The category set Inventory is seeded when you install Oracle Inventory.

The category set Purchasing is seeded when you install Oracle Purchasing.

If you plan to use Order Management’s group pricing functionality with item categories, you must add the categories to the Order Entry category set.

Attention:

1. You must use this window to define valid categories for each purchasing category set before you can use Oracle Purchasing.

2. For the Controlled At level, if the item defining attribute of the functional area (e.g. Inventory’s is Inventory Item) is controlled at the Organization level, then the new default Category Set should also be controlled at the Organization level.

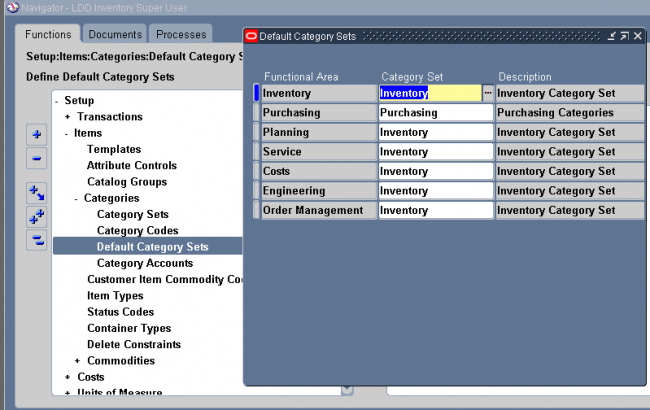

set to each of the following functional areas: Inventory, Purchasing, Order Management, Costing, Engineering, and Planning. Product Line Accounting is seeded with the Inventory category set. Inventory makes the default category set mandatory for all items defined for use by a functional area. If your item is enabled for a particular functional area you cannot delete the item’s corresponding default category set assignment. Default category sets are required so that each functional area has at least one category set that contains all items in that functional area.

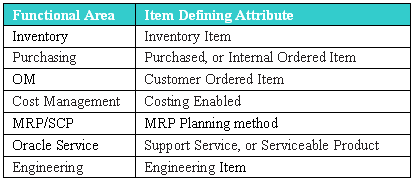

You can enable an item for each functional area by using that functional area’s item defining attribute. An item defining attribute identifies the nature of an item. For example, what designates an item as an “engineering item” is the attribute Engineering Item. If a functional area’s item defining attribute is controlled at the Organization level, then that functional area may only have an Organization level default category set.

When you enable an item for a certain functional area, Oracle Inventory automatically assigns the item to the default category set of that functional area and the default category of that set. For example, if you set Inventory Item to Yes, then Inventory automatically assigns the item to the Inventory functional area’s default category set and default category.

You may change a functional area’s default category set under certain conditions. You should ensure that every item within the functional area belongs to the new default category set (which replaces the existing default category set). If the item defining attribute of the functional area is controlled at the Organization level then the new default category set should also be controlled at the Organization level.

When you enable an item in a functional area, the item is assigned to the default (mandatory) category set and default category of the functional area. You can override the category set’s default category. In addition, you can manually assign your item to an unlimited number of category sets. You may optionally assign an item to more than one category within a category set based on the category set definition.

When you assign your item to another organization Oracle Inventory copies Master level category sets, Organization level default category sets, and the associated categories assigned in the Item Master organization. This means that if you manually assign an Organization level category set to the item in the Master organization, Inventory does not copy over that Organization level category set when you assign that item to another organization.

After assigning an item to another organization you can disable the item for one or more functional areas in the new organization. However, Inventory does not remove the corresponding functional area’s default category set. For example, you may have set the value of the Purchased attribute to ”Yes” when you defined the item in the item master organization. When you assign this item to another organization Inventory copies over the ”Yes” value of the Purchased attribute and

therefore assigns the default category set of the purchasing functional area. In the new organization you may decide to set the value of the Purchased attribute to ”No.” After you disable the item for the purchasing functional area in the new organization, the item still retains the purchasing default category set. You may manually delete the purchasing category set in the new organization.

If you copy an item from another item with category sets defined at the Organization level, Inventory assigns the new item the default categories of the mandatory category sets, even if the original item did not have the default categories. This is because Inventory copies the values of the item defining attributes and not the category sets and categories themselves.

An item is a part or service that you purchase, sell, plan, manufacture, stock, distribute, or prototype. The following Oracle Applications use items:

• Oracle Inventory

• Oracle Purchasing

• Oracle Order Entry

• Oracle Cost Management

• Oracle Bills of Material

• Oracle Work in Process

• Oracle Master Scheduling/MRP

• Oracle Receivables

• Oracle Payables

• Oracle Services

• Oracle Engineering

• Oracle Quality

• Oracle Sales and Marketing

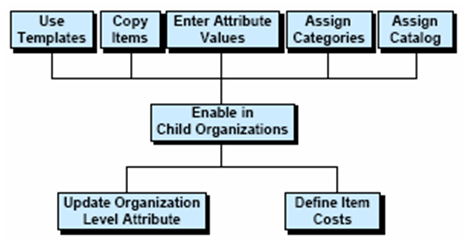

Below diagram describes the basic work that needs to be done before an item is ready to be used in inventory for transaction purpose.

You define items in one organization. To distinguish it from others, we call it the Item Master organization. Other organizations (child organizations) refer to the Item Master for item definition. After you define an item in the Item Master, you can assign it to any number of other organizations.

There is no functional or technical difference between the Item Master organization and other organizations. However, for simplicity, Oracle recommends that you limit the Item Master to just an item definition organization.

Oracle also recommends that you do not define multiple item masters. This can make item definition and maintenance confusing. In addition, multiple item masters are distinct entities, with no relationship to each other. You cannot associate items in one item master organization with another item master organization. You cannot copy items across item

master organizations.

To create the item master:

1. Use the Organization window to create the organization you want to use as the Item Master.

2. Use the Organization Parameters window to specify that organization as the Item Master. This is also where you assign child organizations to the Item Master. The item master organization uses itself as the Item Master.

Item attributes are information about an item, such as order cost, lead time, and revision control.

Item Defining Attributes - An item defining attribute identifies the nature of an item. What designates an item as an “engineering item” is the attribute Engineering Item, but what controls the functionality of the item are the collection of

attributes that describe it. You can buy an engineering item if you want to; simply set Engineering Item, Purchased, and Purchasable to Yes.

The following table presents item defining attributes:

When you set an item defining attribute to Yes, the item is automatically assigned to the default category set of the corresponding functional area. For example, if you set Inventory Item to Yes, the item is automatically assigned to the default category set for the inventory functional area.

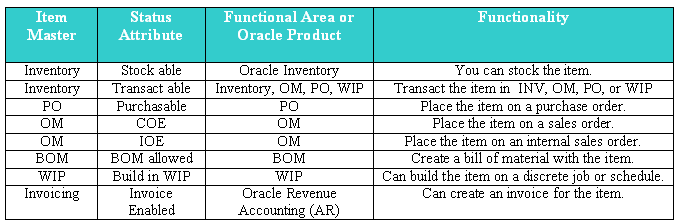

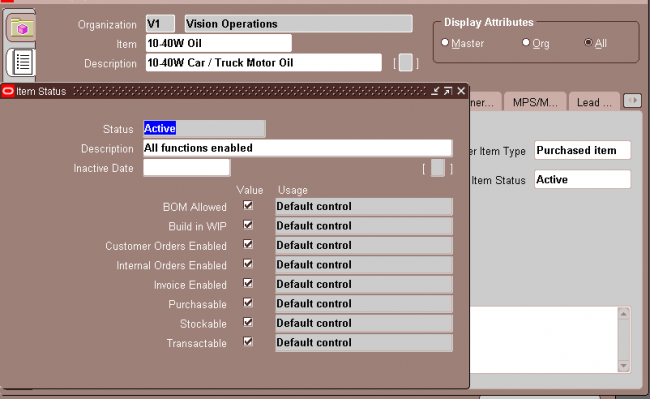

Item Status attributes are item attributes that enable key functionality for each item.

An item status Codes is defined by selecting the value check boxes for the status attributes.

Item Status Codes may be used to set or update the default values for certain item attributes. They can be used to control the functionality of an item. When you update the values for a status, all items that use that status will be updated also.

The Item Status Code controls certain item attributes designated as status attributes. Each status attribute has a Status Setting option. The option determines whether a status attribute value is set by the status code and is not updateable, defaulted and updateable, or not used when you define an item

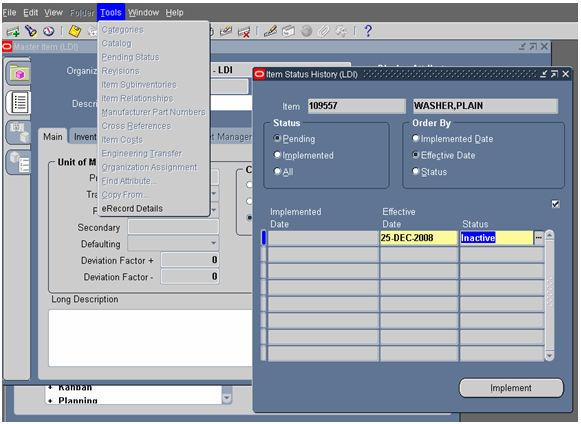

Pending Status:

You can assign one or more pending statuses for an item, to be implemented on future dates. These statuses become effective on their assigned effective dates. You can also view the history of an item status.

(N) Items—>Master Items (M)—>Tools -> Pending Status

You can submit the Update item statuses with the Pending statuses of the concurrent program to update the status of all items with Pending statuses and current effective dates. When you submit this concurrent program, change its parameters so that it resubmits itself periodically, automatically updating item statuses to a Pending status, as effective dates become current. Pending statuses are used in the product development cycle.

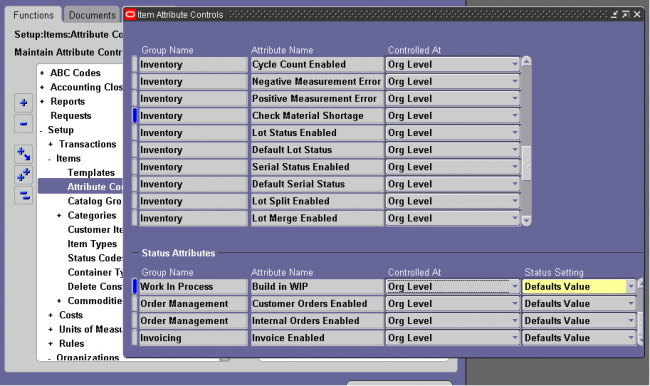

Item Attribute Control determines whether you have centralized (Master level) or decentralized (Organization level) control of item attributes. Both status attributes and item status can be controlled at the item level or organization levels.

You can choose the status setting level of each status attribute in the Item Attribute Controls window. The status setting level determines whether you can update the value of each status attribute within an item status.

Sets Value: The status that you assign to the item loads a non updatable value into the status attribute. You can update the status attribute by changing the status that you assigned to your item.

Defaults Value: The status that you assign to the item loads a default value into the status attribute. You can update the status attribute as you define your item.

Not Used: The status that you assign to the item does not determine the value of the status attribute. You can enable or disable the status attribute as you define your item.

Status Setting Level Consideration: You have the flexibility to change individual status attribute settings. Using meaningful status codes gives you control over item usage.

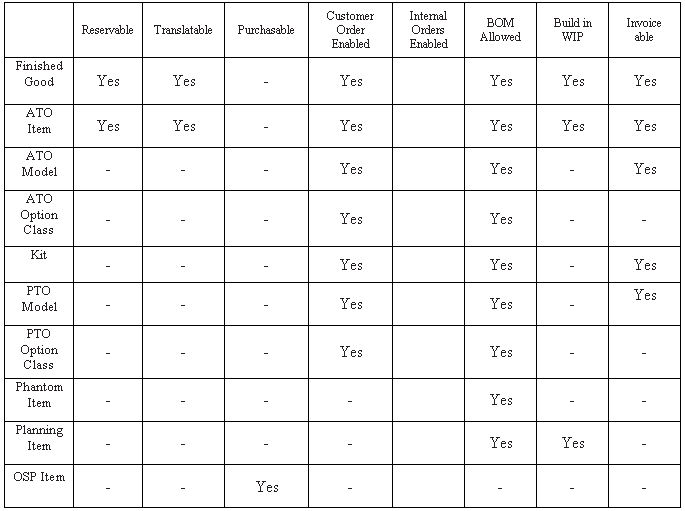

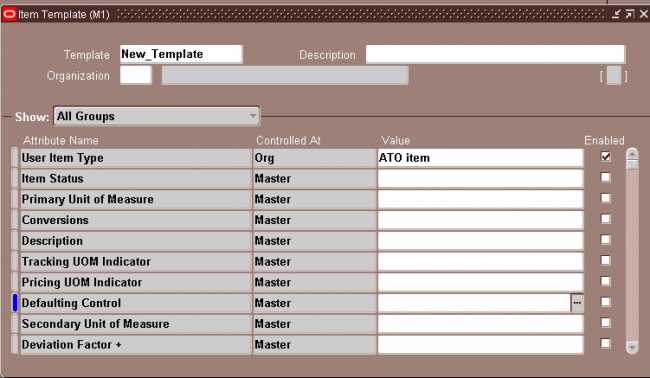

Templates are defined sets of attributes that you can use over and over to create many similar items. Templates make initial item definition easier. Oracle recommends that you use templates—either those Oracle provides or those you define—when you define your items.

Finished Good

ATO Item

ATO Model

ATO Option Class

Kit

PTO Model

PTO Option Class

Phantom Item

Outside Processing Item

Planning Item

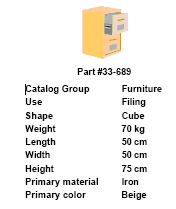

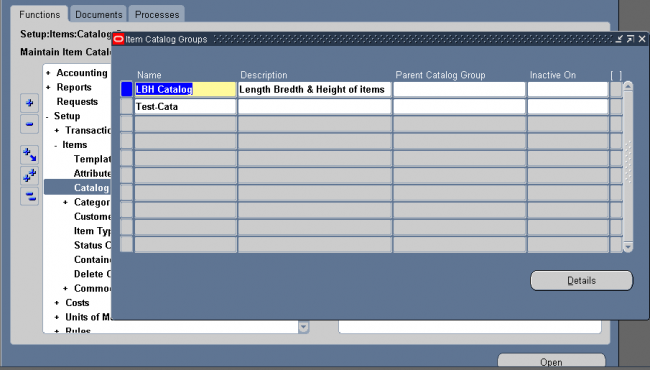

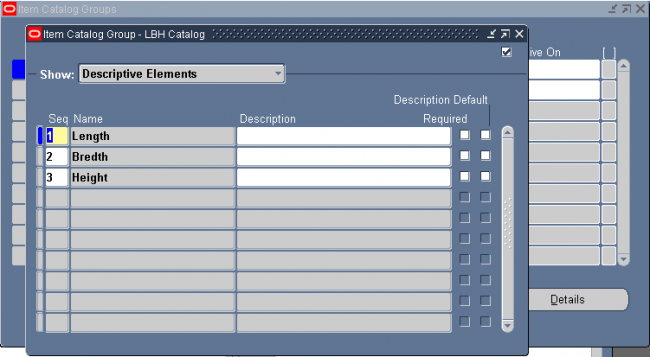

An item catalog group is a standard set of descriptive elements to which you assign items. Examples of catalog descriptive elements are color, shape, length, and so on. For example, a textile manufacturer might define pattern attributes such as color, size, texture, and style.

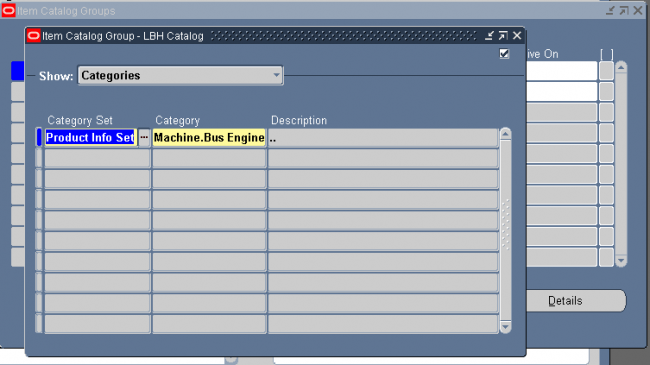

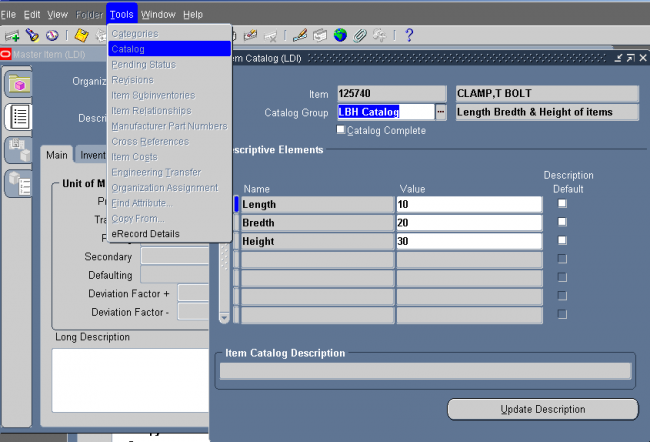

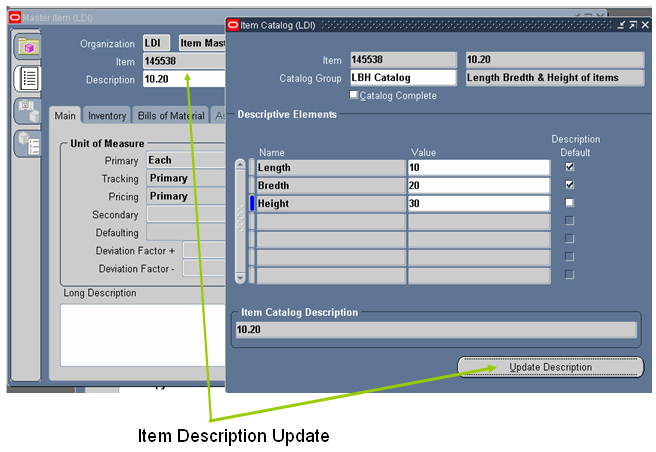

| Usage: An electronics company (say Samsung) can use the catalog to incorporate length, breadth and height of each mobile it produces. As the company Samsung also produces other electronics products such as TV, Refrigerator and etc. We should first create an item category as mobile and then create a catalog group as mobile-catalog with three catalogs length-breadth and height. |

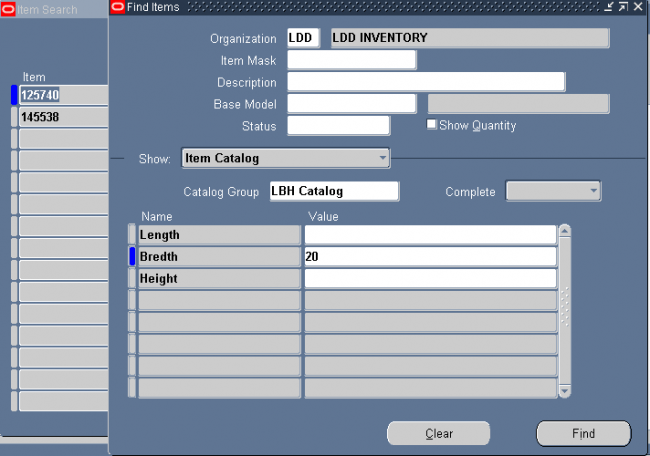

Seraching all the items with bredth 20.

Use the Locations window to define ship–to, bill-to, receiving, office site, internal site & other location information for Purchasing documents.

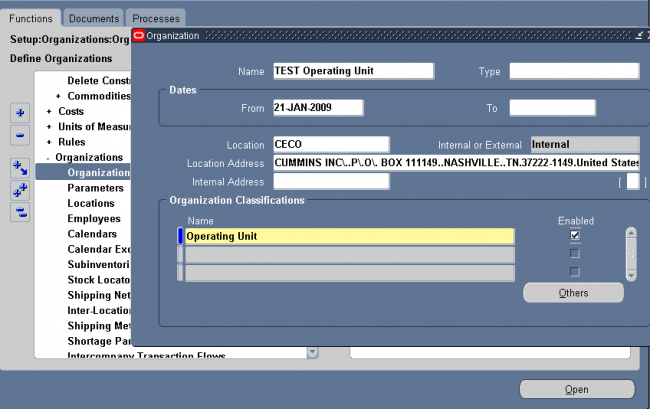

Define the following organizaions as per the requirement of business

i. Business group

ii. Legal Entity

iii. Operating Units

iv. Organization

Enter Organization Classifications & Additional Information

1. Business Group

Business Group Information.

Budget Value Defaults.

Work Day Information.

Benefits Defaults.

PTO Balance Type.

Recruitment Information.

Payslip Information.

Self Service Preference Information.

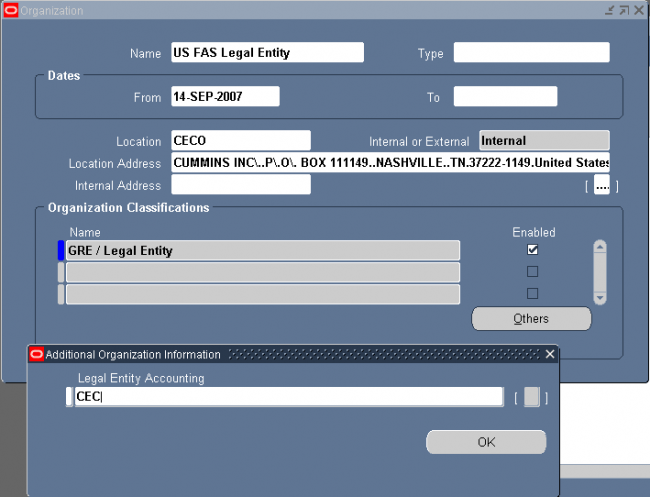

2. Attaching Set of Books to Legal Entity

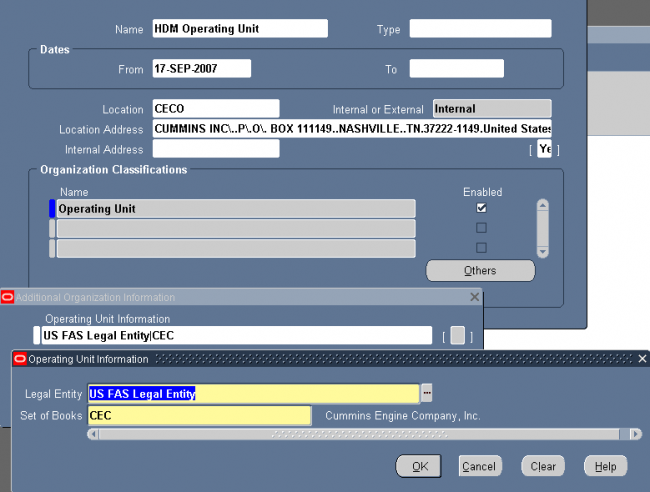

3. Attaching Set of Books & Legal Entity to Operating Unit

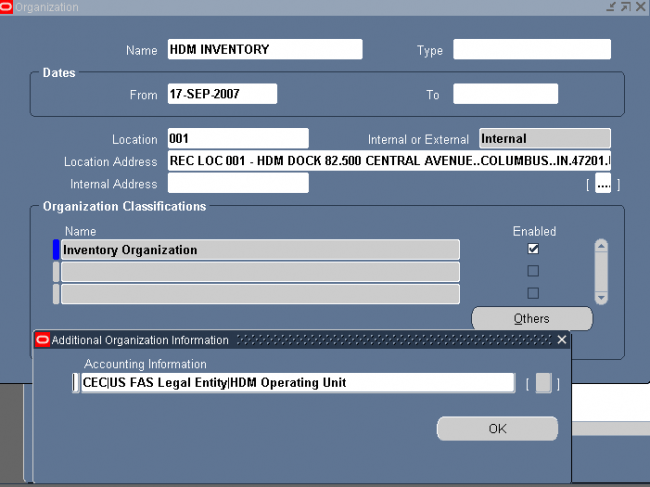

4. Attaching Operating Unit to organization

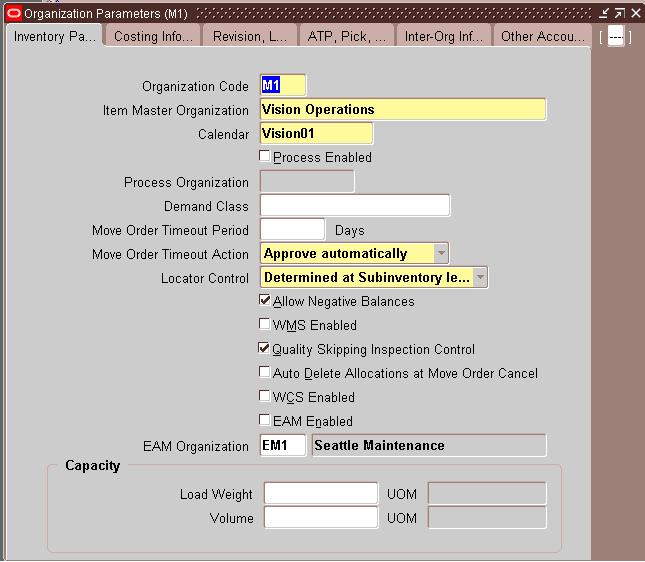

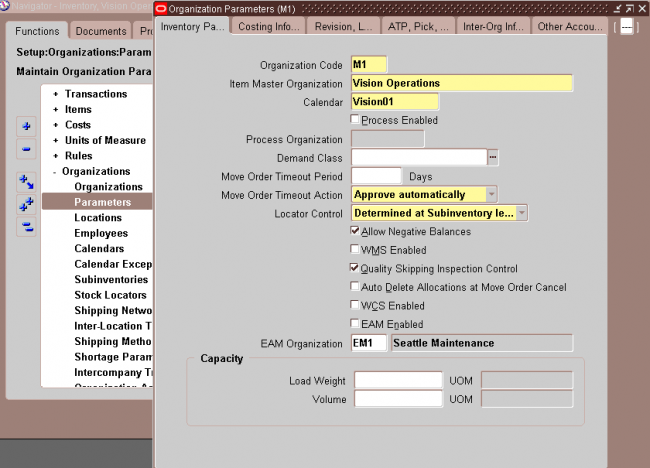

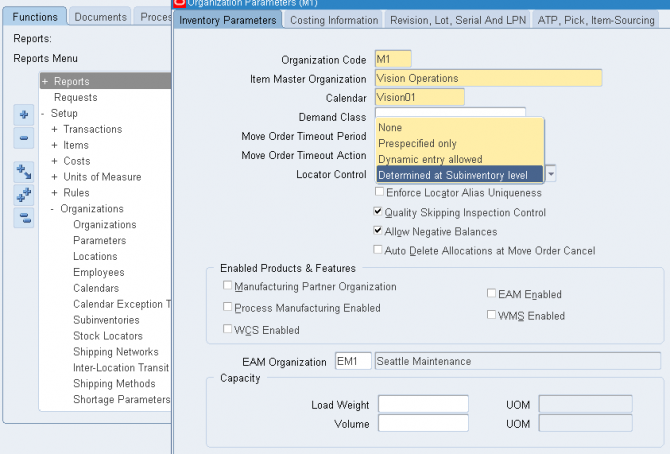

You can define and update default inventory and costing parameters for your current organization in the following areas:

1. Enter an organization code for which you want to set up the organization parameter.

2. Select an Item Master organization. Oracle Inventory only defines items in the Item Master organization of the organization from which you enter the Items window.

3. Select a workday calendar. This is required when Oracle Master Scheduling/MRP and Oracle Supply Chain Planning is installed.

4. Optionally, select a demand class. Demand classes segregate scheduled demand and production into groups, allowing you to track and consume those groups independently. Oracle Master Scheduling/MRP and Oracle Supply Chain Planning uses this demand class during forecast consumption, and shipment and production relief.

5. In the Move Order Timeout Period field, enter the number of days a move order requisition can wait for approval.

The workflow approval process sends a notification to the item planner when a move order requisition requires approval. After the first timeout period, if the recipient has not approved or rejected the order, a reminder notice is sent. After the second timeout period, the order is automatically approved or rejected, depending on whether you select Approve automatically or Reject automatically in the Move Order Timeout Action field. If you want to bypass the move order approval process and automatically approve move order requisitions, enter 0 days in the Move Order Timeout Period field and select Approve automatically in the Move Order Timeout Action field.

6. Select a move order timeout action

Approve automatically: After the second timeout period, move order requisitions are automatically approved. Select this option and set the Move Order Timeout Period to 0 if you want to bypass the move order approval process and automatically approve move order requisitions.

Reject automatically: After the second timeout period, move order requisitions are automatically rejected.

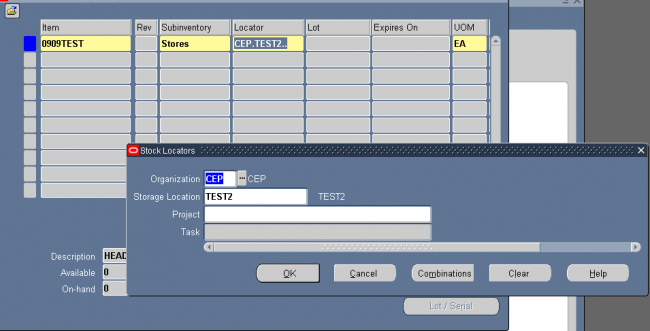

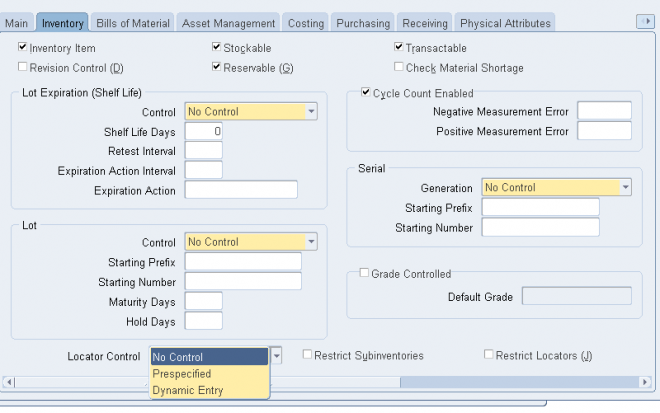

7. Select a locator control option:

None: Inventory transactions within this organization do not require locator information.

Prespecified only: Inventory transactions within this organization require a valid, predefined locator for each item.

Dynamic entry allowed: Inventory transactions within this organization require a locator for each item. You can choose a valid, predefined locator, or define a locator dynamically at the time of transaction.

Determined at subinventory level: Inventory transactions use locator control information that you define at the subinventory level.

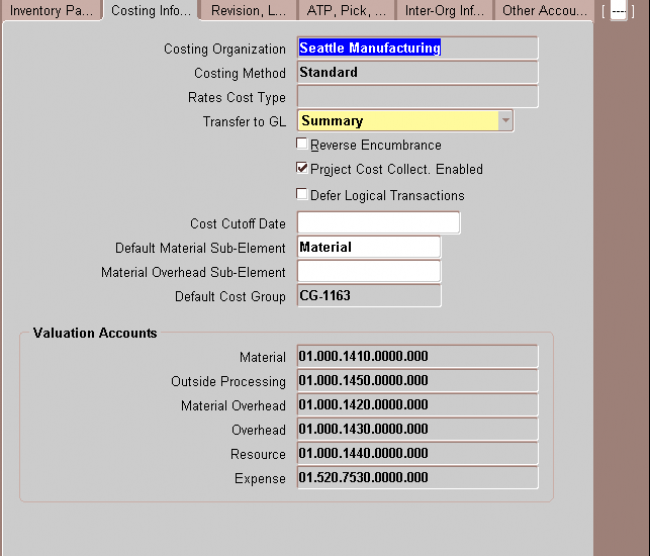

The costing organization that controls the costs in your current organization and the costing method are displayed. You cannot make changes to these fields.

1. Costing Organization

2. Costing Method

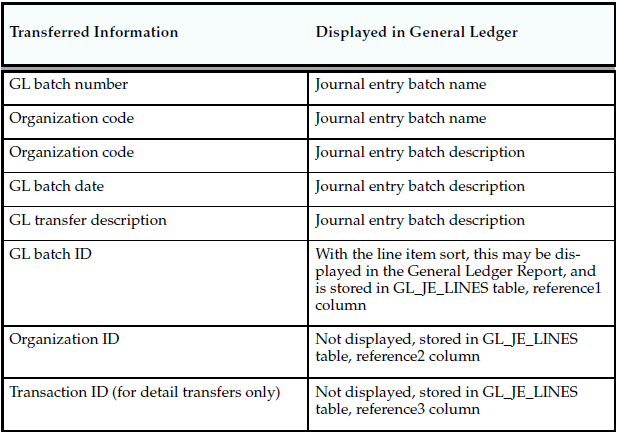

3. Transfer to GL Indicate whether all transactions are posted in detail to the general ledger.

Caution: Transferring detail transaction distributions to the general ledger increases general ledger posting times due to the number of records created.

4. Reverse Encumbrance Indicate whether to reverse encumbrance entry upon receipt in inventory.

You normally select this option if you use encumbrances with Oracle Purchasing.

5. Optionally, enter a Cost Cutoff Date

If you leave this field blank, all available transactions will be costed,as usual. If you enter a date, all transactions prior to this date will be costed. All transactions on or later than this date will not be costed.

For inter–organization transfers, a standard costing, receiving organization will not cost a receipt if the sending organization did not already cost the transaction.

The default time is the first instant of the date. You can optionally choose another time.

The standard cost update process can be performed on the cost cutoff date. You can restart cost processing by changing the cutoff date to blank, or a future date.

6. Default Material Sub element

For standard costing, select a material sub–element that this organization uses as a default when you define item costs. For average costing, the default material sub–element you select can be used for cost collection when Project Cost Collection Enabled is set.

7. Material Over head Sub element

Optionally, select a Default Material Overhead Sub–Element from the list of values. During the Supply Chain Rollup process, when costs are merged from another organization, markup and shipping costs will use this value.

The supply chain cost rollup will complete successfully, regardless of whether this field is populated. If the Cost Rollup identifies an organization with a default material overhead sub–element not set up, a corresponding warning message will be printed in the log file.

8. Default Cost Group

Indicate the default cost group for the organization. This will default into the Default Cost Group field for each subinventory. If the WMS cost group rules engine fails to find a cost group, this cost group will be used.

9. Valuation Accounts

You choose a default valuation account when you define organization parameters. Under standard costing, these accounts are defaulted when you define subinventories and can be overridden. Under average costing, these accounts (except for Expense) are used for subinventory transactions and cannot be updated. For a detailed discussion of cost

elements.

Material An asset account that tracks material cost. For average costing, this account holds your inventory

and intransit values. Once you perform transactions, you cannot change this account.

Material Overhead An asset account that tracks material overhead cost.

Resource An asset account that tracks resource cost.

Overhead An asset account that tracks resource and outside processing overheads.

Outside processing An asset account that tracks outside processing cost.

Expense The expense account used when tracking a non–asset item.

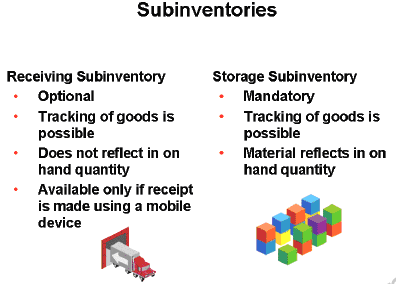

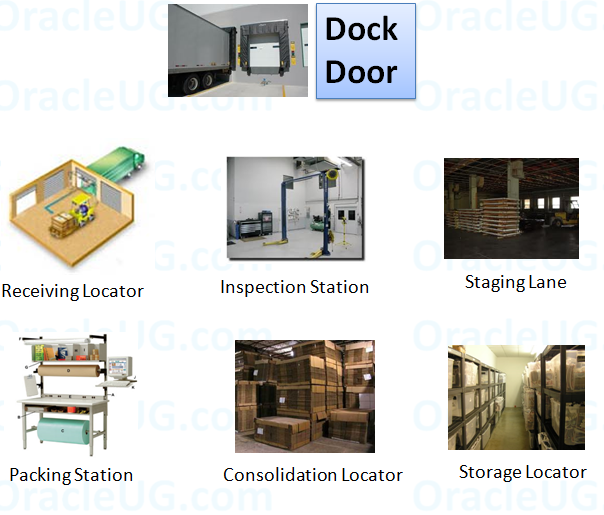

Subinventories are unique physical or logical separations of material inventory, such as raw inventory, finished goods, or defective material. All material within an organization resides in a subinventory. There are two types of subinventories within Warehouse Management, storage and receiving.

Storage subinventories are intermediate or final put away locations for material. Material that resides in a storage subinventory appears in on hand quantity, and is tracked by the system. The system can book orders against, and use manufacturing processes on material that resides in a storage subinventory. You must define at least one storage subinventory for your implementation.

Optionally, you can create receiving subinventories to track material in the receiving area. You use receiving subinventories when you want to track the material as soon as it enters the warehouse before an operator puts it away. Receiving subinventories enable managers to see where the material resides as soon as it enters the warehouse. Material located in a receiving subinventory does not appear in on hand quantity, and the system cannot reserve the material.

An operator can also only specify a receiving subinventory if they are using a mobile device to receive the material.

Note: Operators cannot transfer material from a storage subinventory to a receiving subinventory.

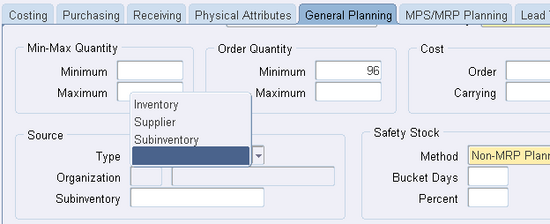

Select a source type for item replenishment.

You use locators to identify physical areas where you store inventory items. Item quantities can be tracked by locator. Items can also be restricted to specific locators.

1. Add the segment values of the KFF stock locator.

Navigation : GL -> Financials -> Flexfields -> Key -> Values

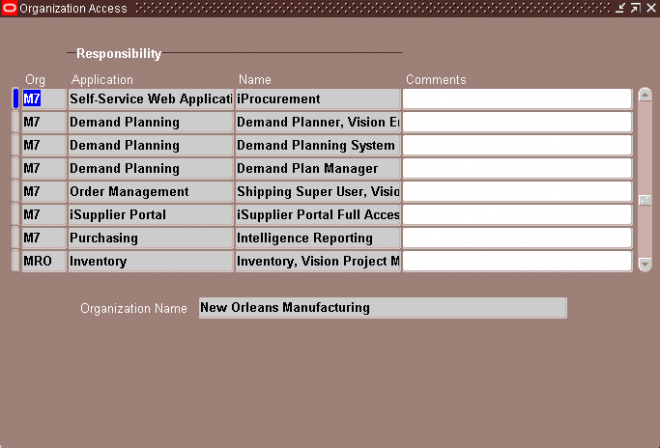

You can specify which organizations a responsibility can access by mapping responsibilities to organizations. Once this mapping is set up, a user logging into an Oracle Manufacturing product is restricted to the organizations mapped to the responsibility chosen. The Change Organization window is restricted as well.

Attention: Until you assign an organization to a responsibility in this window, all responsibilities have access to all organizations. Once you have restricted any responsibility to an organization, you must then explicitly define the organizations which all responsibilities can access.

Attention: This feature does not restrict access once the user is in the product. Users with access to functions that cross multiple organizations (such as ATP, Inter–organization Transfers, Item Search, Multi–organization Quantity Report, and so on) can still specify any valid organization when running these functions.

You can enable the system to send material shortage alerts and shortage notifications when a material shortage occurs in an organization. A material shortage occurs whenever unsatisfied demand exceeds available quantity for incoming supply of material.

The concept of customer item is to link the customer item with the inventory item of the organization so that the customer can order with their customer item for which we have a refernce to the inventory item. To facilitate the process we use commodity code to group all the customer items.

A customer item defined at the Customer level is recognized across all address and address categories for that customer. If you ship an item to multiple customer ship–to sites that have been grouped as an address category, you can define the customer item for that address category. You would define a customer item at the address level if you ship the item to only one ship–to site for that customer.

Commodity Codes

Customer Item Commodity Codes are used to group customer items and can be entered during the definition of customer items.

Navigation : INV -> Setup ->Items -> Customer Item commodity code.

Customer Item

1. Select one of the existing Customer Names (in the Details window, you can use either Customer Name or Customer Number,).

2. Select the Definition Level: Customer, Address Category, or Address.

A customer item defined at the Customer level is recognized across all address and address categories for that customer. If you ship an item to multiple customer ship-to sites that have been grouped as an address category, you can define the customer item for that address category. You would define a customer item at the address level if you ship the item to only one ship-to site for that customer.

For the Address Category definition level, enter the address category.

For the Customer Address definition level, enter the customer address.

3. Enter the Customer Item number and description.

4. In the Commodity tabbed region, you can assign the customer item to a Commodity Code.

5. In the Container tabbed region, you can enter the default master and detail containers for this customer item as well as the minimum fill percent for the container.

6. In the Model, Departure Planning tabbed region, you can reference a customer item as a Model by entering the inventory item number of an existing Model item (the BOM Item Type attribute is set to Model).

You can also check Required to indicate that items must be departure planned before they released and Before Build to indicate that ATO items must be departure planned before they are built.

7. In the Demand Tolerances, Active tabbed region, you can enter positive and negative tolerance percentages and select or deselect the Active check box.

Customer Item Cross References

Use the Customer Item Cross References window to define and update cross references between your inventory items and the customer item numbers defined in the Customer Items Summary/Detail windows.

You can also navigate to this window by selecting the Cross Reference button in the Customer Items Summary window. Inventory displays the existing cross references for the customeritem on the current line in the Customer Items Summary window, and you can add new cross references by selecting a new row.

Enter the Rank as a positive number. To permit alternate or substitute inventory items for a customer item, you can define multiple cross references to inventory items for a single customer item. In these cases, you must specify the Rank of the cross reference. The highest rank is 1.

Cross–reference types define relationships between items and entities such as old item numbers or supplier item numbers. For example, you can create a cross–reference type Old to track the old item numbers, and a type Supplier to track supplier part numbers.

You must set certain controls and reference options before defining items. These enable you to maintain, group, reference, query, and delete your items. Once you have defined items, you can set up other parameters, such as item cross references, to control the use of items.

You define items in one organization. To distinguish it from others, we call it the Item Master organization. Other organizations (child organizations) refer to the Item Master for item definition. After you define an item in the Item Master, you can assign it to any number of other organizations.

There is no functional or technical difference between the Item Master organization and other organizations. However, for simplicity, Oracle recommends that you limit the Item Master to just an item definition organization.

Oracle also recommends that you do not define multiple item masters. This can make item definition and maintenance confusing. In addition, multiple item masters are distinct entities, with no relationship to each other. You cannot associate items in one item master organization with another item master organization. You cannot copy items across item master organizations.

To create the item master:

1. Use the Organization window to create the organization you want to use as the Item Master.

2. Use the Organization Parameters window to specify that organization as the Item Master.

Item Master Business Example

Suppose you have a distribution warehouse and a manufacturing factory. In the warehouse, the item has independent demand and is min–max planned. In the factory, the item is MRP planned and built.

Using an Item Master with a warehouse and a factory as the other organizations, you define the item just once—in the Item Master. Next, you assign the item to both the warehouse and the factory. Finally, you change the planning and build attributes in each organization to

describe the different behavior of the items in those organizations. You do not have to change any other information about the item; in fact, because information such as unit of measure, description, and so on is maintained at the Master level, you know it is consistent in each organization

Inventory Attribute Group

Following are the Inventory attributes and their possible values. You set these attributes when defining or updating items.

Following are the Order Management attributes and their possible values. You set these attributes when defining or updating items.

Customer Ordered

Indicate whether to allow an item to be ordered by external customers. You can add any customer orderable items to price lists in Oracle Order Management. This attribute must be turned off if the BOM Item Type attribute is set to Planning.

If you turn this attribute on, you can temporarily exclude an item from being ordered by turning Customer Orders Enabled off. This is an item defining attribute. If you turn this attribute on, the item is automatically assigned to the default category set for the Oracle Order Management functional area.

Customer Orders Enabled

Indicate whether an item is currently customer orderable. If you turn this attribute on you can specify the item in the Enter Orders window in Oracle Order Management.

You can initially define an item with Customer Ordered Item turned on and Customer Orders Enabled turned off. This means prices can be defined for the item, but no orders can be placed for it.

Internal Ordered

Indicate whether to allow an item to be ordered on an internal requisition.

If you turn this attribute on, you can temporarily exclude an item from being ordered on an internal requisition by turning Internal Orders Enabled off.

This is an item defining attribute. If you turn this attribute on, the item is automatically assigned to the default category set for the Oracle Purchasing functional area.

Internal Orders Enabled

Indicate whether you can currently order an item internally. If you turn this attribute on, you can specify the item on an internal requisition, if Internal Ordered Item is also on.

If you turn Internal Ordered Item on, you can temporarily exclude an item from being ordered on an internal requisition by turning this attribute off.

This attribute is optionally set by the Item Status code.

Shippable

Indicate whether to ship an item to a customer. Shippable items are released by Oracle Shipping Execution’s Pick Release program, creating confirmable shipping lines, and are printed on the pick slip. A warning is issued if you change the value of this attribute when open sales order lines exist.

This attribute must be turned off if the BOM Item Type attribute is set to Planning.

OE Transactable

Indicate whether demand can be placed for an item by Oracle Order Management, and whether shipment transactions are interfaced to Oracle Inventory. Most items with Shippable turned on also have OE Transactable turned on. For items you do not ship, you may still want OE Transactable turned on if you use the items in forecasting or planning.

If you also want to reserve the item, turn Reservable on. A warning is issued if you change the value of this attribute when open sales order lines exist. You cannot turn this attribute off if demand exits.

Pick Components

Indicate whether an item has a bill of material with options, classes, or included items picked from finished goods inventory. Pick–to–order items must have this attribute turned on. Assemble–to–order items and items without a bill of material must have this attribute turned off.

Assemble to Order

Turn this attribute on if an item is generally built for sales order demand; a final assembly work order is created based on sales order details. You must turn on this attribute if you auto create requisitions.

An item cannot have Pick Components turned on and this attribute turned on at the same time.

Returnable

Indicate whether to allow customers to return an item. If an item is returnable, you can enter it on the Returns window in Oracle Order Management. Order Management uses this attribute along with Stockable and Transactable to determine which authorized returned items

you can physically receive into inventory.

RMA Inspection Required

Indicate whether inspection is required for items returned by the customer. The item then must be separately transferred to inventory.

Credits are never automatically generated by Oracle Order Management for customer return items awaiting inspection.

Financing Allowed

Indicate whether a customer can finance this item.

ORDER DETAILS

Check ATP

Select Check Material Only, Check Material and Resources, Check Resources Only, or None to indicate whether to check available to promise and/or capable to promise information when placing demand.

This attribute also determines whether you can view component ATP information for material requirements in Work in Process.

ATP Components

Indicate whether to include, in available to promise checking, additional components in the bill of material for ATO and PTO items. These components are included in ATP checking if Check ATP for the component is turned on.

ATP Rule

Enter a user–defined available to promise rule. ATP rules define supply and demand sources, time–fence parameters, and available–to–promise calculation methods. You can give ATP rules meaningful names, such as ATO ATP Rule.

If there is no ATP rule for the item, the organization’s default ATP rule is used.

Default Shipping Organization

Enter the Oracle Shipping Execution primary shipping organization. This organization defaults to the Enter Orders window if Item is the source attribute of the Warehouse object in the standard value rule set for the order. This organization defaults to the Enter Returns window if a receiving warehouse is not defined on the customer or order type.

Default SO Source Type

This item attribute determines if an item is to be drop–shipped. If the value is internal, the item will not be drop–shipped. If the value is external, the item will be drop–shipped.

Picking Rule

Enter the picking rule that defines the order in which subinventories, locators, lots, and revisions are picked. This rule will not be employed in WMS enabled organizations. Oracle Warehouse Management picking rules will be used.

Following are the Purchasing attributes and their possible values. You set these attributes when defining or updating items.

Purchased

Indicate whether to purchase and receive an item. Turning this option on allows you to set the Purchasable attribute.

This is an item defining attribute. If you turn this option on, the item is automatically assigned to the default category set for the Oracle Purchasing functional area.

If an item is vendor managed, you must turn on this option.

Purchasable

Indicate whether to order an item on a purchase order. You can set this only when Purchased is turned on.

Turning Purchasable off allows you to temporarily restrict the ability to buy. This attribute is optionally set by the Item Status code.

RFQ Required

Indicate whether to require an item quotation when requesting an item. Oracle Purchasing defaults this value on requisition lines for this item. Leave this field blank if you want Inventory to use the value defined in the Purchasing Options window for transactions involving this item.

Taxable

Indicate whether the supplier charges a tax. Oracle Purchasing uses the taxable status together with the tax code you associate with a location to determine whether a purchase order shipment is taxable, and what the tax code that applies to this shipment is. Leave this field blank if you want Inventory to use the value defined in the window for transactions involving this item.

Tax Code

Select the appropriate tax code for the item. The tax code shows the tax authorities and rates that are available to use for this item. You must select the taxable attribute to enable this field.

Receipt Required (Three–Way Invoice Matching)

Indicate whether you must receive an item before you can pay the invoice. Leave this field blank if you want Inventory to use the value defined in the Purchasing Options window for transactions involving this item.

Inspection Required (Four–Way Invoice Matching)

Indicate whether to inspect an item upon receipt from the supplier, before paying the corresponding invoice. Leave this field blank if you want Inventory to use the value defined in the Purchasing Options window for transactions involving this item.

Outside Processing Item

Indicate whether you can add the item to an outside processing purchase order line. You can turn this option on only if Purchased is also on. In addition, this option controls whether you can attach an item to a resource in the Resource window.

Outside Processing Unit Type

Select an option to determine the quantity of an outside processing item you requisition, purchase and receive:

Assembly You purchase an outside processing item based on the number of assemblies you ship to the supplier.

Resource You purchase an outside processing item based on the number of assemblies times the resource usage rate or amount.

Following are the Receiving attributes and their possible values. You set these attributes when defining or updating items.

Following are the Bills of Material attributes and their possible values. You set these attributes when defining or updating items

BOM Allowed

Allows you to define a bill of material for an item, or to assign the item as a component on a bill.

This attribute is optionally set by the Item Status code.

BOM Item Type

Following are the Costing attributes and their possible values. You set these attributes when defining or updating items.

Following are the Work In Process attributes and their possible values. You set these attributes when defining or updating items.

Following are the General Planning attributes and their possible values. You set these attributes when defining or updating items.

Inventory Planning Method

Select an option for organization level planning.

Min–max You define a minimum quantity that you want on hand. When you reach this quantity, you reorder. You also define a maximum on–hand quantity that you do not want to exceed.

Not planned No planning method used. Select this option for MRP/MPS planned items.

Reorder point The reorder point is calculated based on the planning information you define for this item.

Planner

This attribute is controlled at the Organization level only. Enter the material planner assigned to plan this item. You must define planner codes for your organization before updating this attribute. The planner defined here is responsible for approving all move order lines requesting the item if move order approvals are used.

If an item is vendor managed, you must enter a planner for the item.

Make or Buy

Select the option that applies to items with Inventory Item set to Yes. The Planner Workbench uses this to default an appropriate value for implementation type. You cannot change the value of the flag if open orders exist for the item.

Make Usually manufactured. The Planner Workbench defaults the implementation type Discrete job. The planning process passes demand down from manufactured items to lower level components.

Buy Uslly purchased. The Planner Workbench defaults the implementation type to Purchase Requisition. The planning process does not pass demand down from purchased items to lower level components.

Attention: You must also set Purchasable to Yes to create purchase requisitions and purchase orders. If you also set Build in WIP to Yes, you can use the Planner Workbench to implement planned orders as discrete jobs.

Following are the Invoicing attributes and their possible values. You set these attributes when defining or updating items

In this chapter we‘ll discuss some advance controls that oracle provides on items

You can define relationships between items. This allows you to search for items through these relationships. Except in Oracle Purchasing, these relationships are for inquiry and reporting purposes only.

Item Relationships with Oracle Purchasing

Within Oracle Purchasing you can define acceptable substitute items for receiving. You must define a list of substitutes before you receive a substitute item in place of an originally ordered item. Attention: If you receive a substitute item, you must have previously defined a unit of measure conversion between the unit of measure on the purchase order and the unit of measure on the receipt.

Cross–Sell: This relationship indicates that one item may be sold in lieu of another item.

Up–Sell: This relationship indicates that a newer version of the item exists, and can be sold in place of the older item.

Service: This relationship establishes service items for a repairable item.

Prerequisite: This relationship indicates that you must possess one of the items as a requirement to possessing the other item.

Collateral: This relationship indicates collateral, such as marketing brochures, that you possess for an item.

Superceded: This relationship indicates that one item has replaced another item that is no longer available.

Complimentary: This relationship indicates if a customer purchases one item, the other item is received for free.

Impact: This relationship is used to relate items to each other but only under special conditions.

Conflict: This relationship indicates that these items may never be used together.

Mandatory Charge: This relationship indcates a mandatory charge if the customer purchases both items.

Optional Charge: This relationship indicates an optional charge if the customer purchases both items.

Promotional Upgrade: This relationship enables a customer to upgrade from one item to another item or equal or higher value, without an additional charge.

Split: This relationship enables you to split support for an item so you do not have to manually split support at contract renewal. To use this relationship, you must be in a planning enabled organization.

Merge: This relationship enables rules based consolidation of contracts. You may use the earliest or latest target end date for consolidation. This allows you to choose how contracts are consolidated. To use this relationship, you must be in a planning enabled organization.

Migration: During contact renewal you are given the option of renewing contracts based on new licenses, or old licenses. To use this relationship, you must be in a planning enabled organization.

Repair to: You use the Repair to item relationship with field service operations that use spares management functionality. If a part has been superseded by another part, the Repair to item relationship determines the replacement part.

You can define manufacturer part numbers for items. You can use this information for reporting purposes; and in catalog searches for particular items.

Navigate to the Manufacturers window , Enter the name of the manufacturer & Save your work.

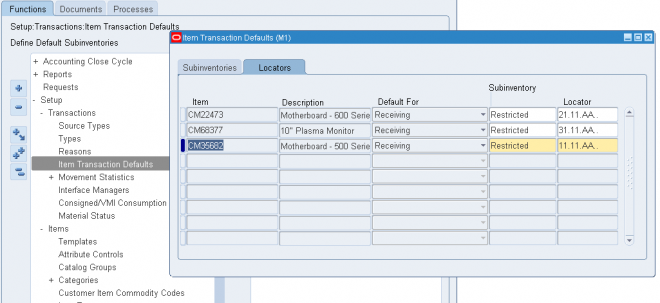

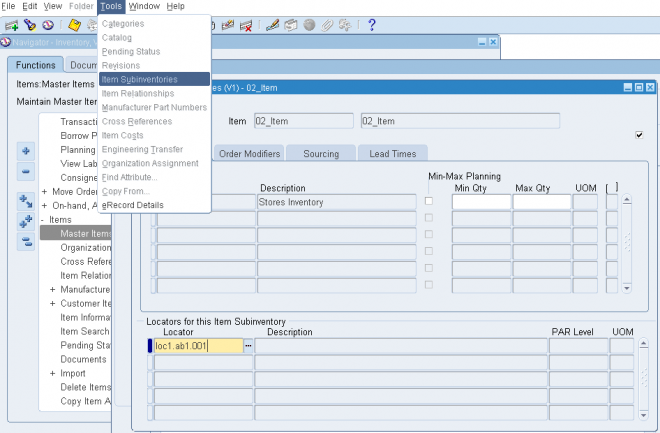

Assigning Subinventories to an Item

You can assign a list of subinventories to an item. You restrict an item to the list of subinventories by setting the Restrict Subinventories attribute when you define or update the item.

Use this form to define a default subinventory and/or locator for an item for shipping, receiving, and move order transactions. Oracle Shipping Execution displays the default shipping information when you ship an item. Oracle Inventory displays the default receiving information when you receive an item. For move orders, Oracle Inventory derives the default put away locator when you transact an item into a locator controlled subinventory if no locator was specified by the creator of the move order.

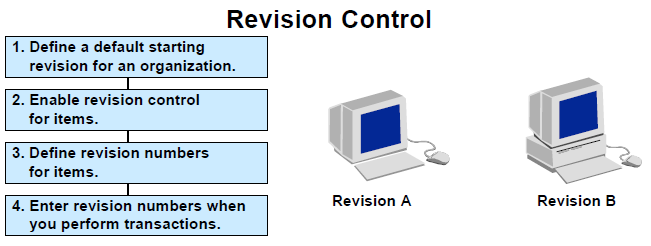

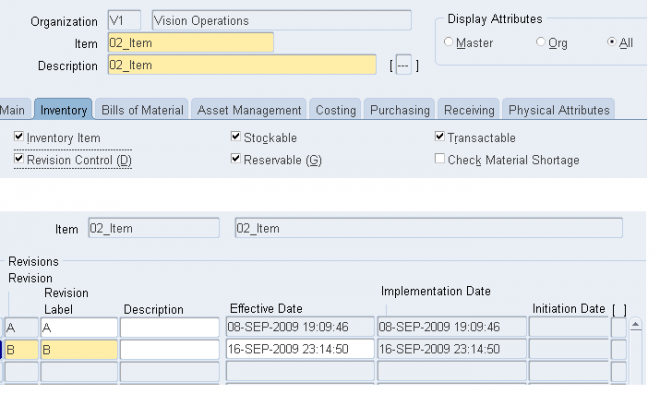

Navigate to the Item Revisions window from one of the following windows:

i.Master Items Summary folder or Master Item window

ii. Organization Items Summary folder or Organization Item window

iii. Bills of Material window

iv. Engineering Change Orders window

You can use letters, numbers, and characters (such as *, &, and #) to label revisions. Letters are always in upper case and numbers may include decimals. To ensure that revisions sort properly, decimals should always be followed by a number. Valid revisions can include: A, B, 01, 02, A1, B1, 1A, 1B, 0.0, 0.1, A.0, A.1, and so on.

Revisions are sorted according to ASCII rules. Each revision must be greater than the previous revision. Therefore, you cannot use revision 10 after revision 9 because, according to ASCII sorting, 10 precedes 9.

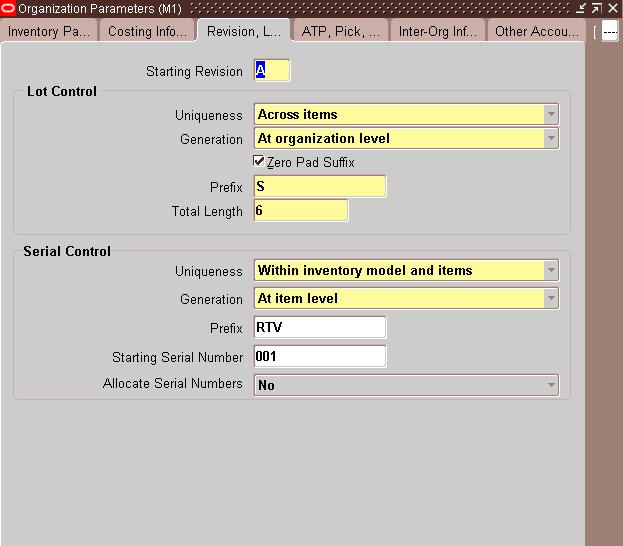

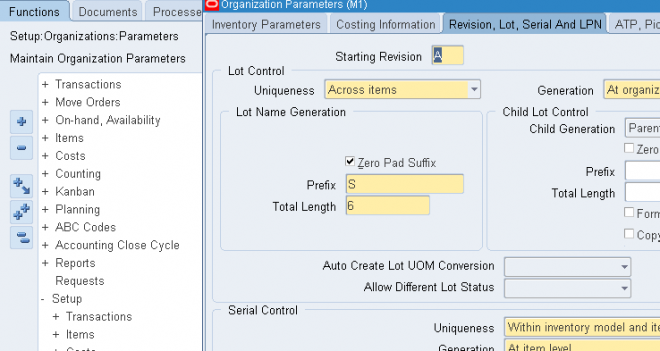

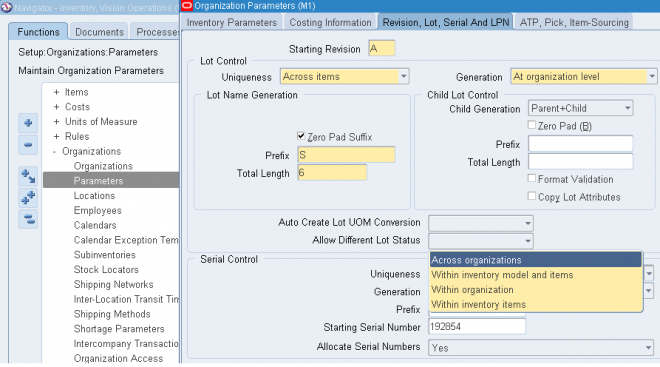

The value you entered in the Starting Revision field in the Organization Parameters window displays as the starting revision for the item. For revisions that have the same effective date, the revisions sort in descending order starting with the last revision you entered.

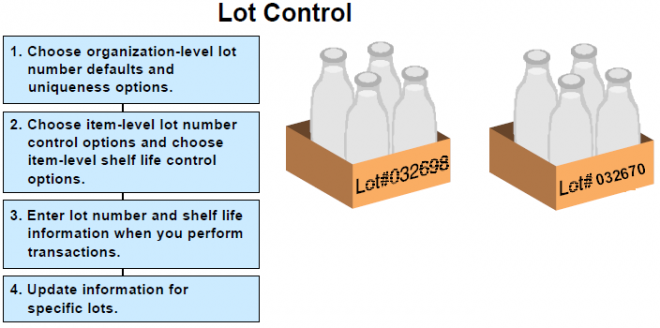

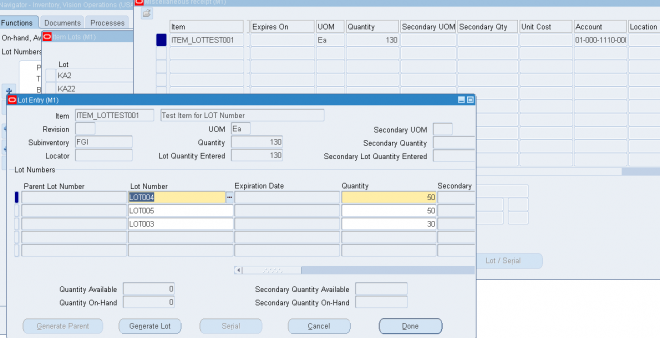

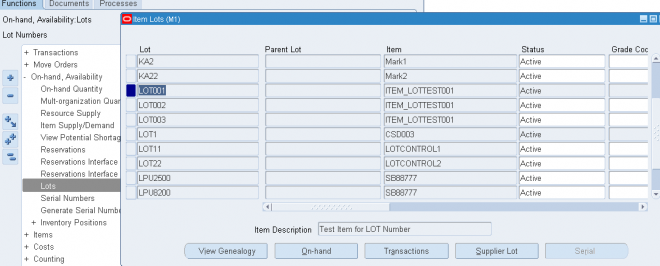

Oracle Inventory provides complete lot number support for inventory transactions. You can enable lot control for specific items in your inventory. For items under lot control, you assign lot numbers to each receipt into inventory and thereafter reference the same lots each time you perform material transactions. This allows you to have tight control over batches of items in your inventory.

Assigning Lot Numbers

Issuing Material from Inventory

When you issue items under lot control from inventory, you must specify a lot number for that item. You can specify more than one lot to cover the transaction quantity. If you attempt to transact an item to or from an expired lot, Inventory displays a warning message but does not prevent you from using the lot.

Assigning Lot Numbers to Assemblies

When you complete an assembly under lot control into inventory, you must assign a lot number in the WIP Completion Transaction form in Oracle Work in Process. For assembly completions on discrete jobs, Oracle Work in Process defaults the job’s lot number.

Purging Lot Transactions

You can purge all lot transaction information from your current organization. Note that the transactions must be in closed accounting periods.

Attention: Purging lot transactions eliminates information used in lot genealogy reports and inquiries (Supplier Lot Trace Report, Job Lot Composition Report, and Job Lot Composition Inquiry).

Maintaining Lot Number Information

You can use the Item Lots window to update the expiration date of lots for items under lot expiration (shelf–life) control. Inventory lets you view all lots you created in your current organization and the supplier lot information associated with them.

Expired Lots

You can determine whether a lot has an expiration date by assigning a number of lot control shelf life days or by entering an lot expiration date. The expiration date controls the availability of the lot for transacting and planning purposes. An expired lot:

• is not considered as on–hand supply when performing min–max, reorder point or MRP planning calculations

• cannot be reserved for a date beyond the expiration date

• can be transacted and is included in on–hand quantities

• is included in all inquiries and reports, including inventory valuation reports

• is included in a cycle count and count entry and adjustments are allowed

• is included in a physical inventory and tag entry and adjustments are allowed

Disabled Lots

Disabling a lot only prevents it from appearing in a list of values when performing receipt transactions. If you type in the lot number it is valid and acccepted even though it was not in the list of values. Disabling is used only for tailoring this specific instance of the list of values for lot numbers. A disabled lot:

• is included in available to transact, available to promise, and available to reserve calculations

• is included as on–hand supply when performing min–max, reorder point or MRP planning calculations

• is included as on–hand in all inquiries and reports, including inventory valuation reports

• can be transacted with Inventory functions and the Transaction Open Interface

• can be reserved

Cycle Counting

Inventory includes the lot numbers of the items to cycle count when it generates a cycle count listing. You must assign lot numbers to all items under lot control for which you enter counts. If there is a difference between the count quantity and the system on–hand

quantity, Inventory adjusts the item quantity in that lot.

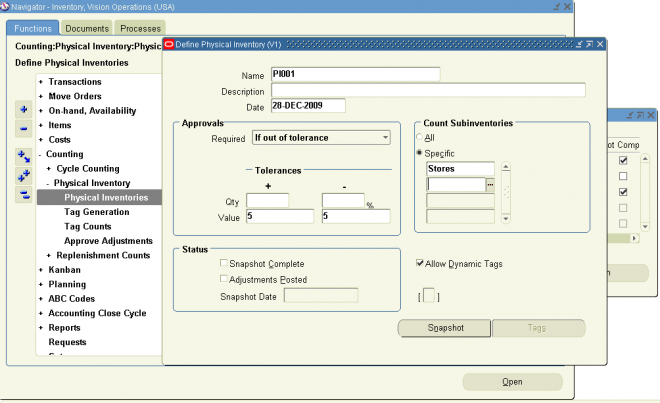

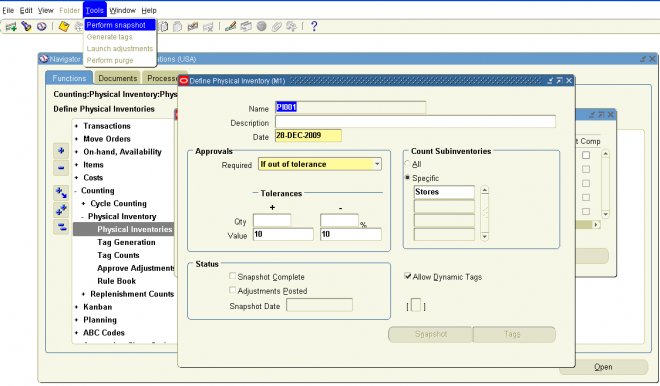

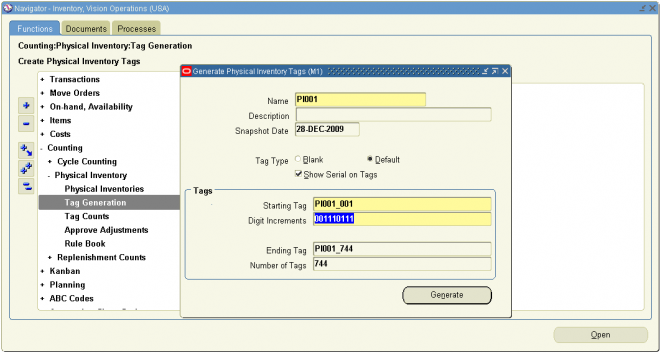

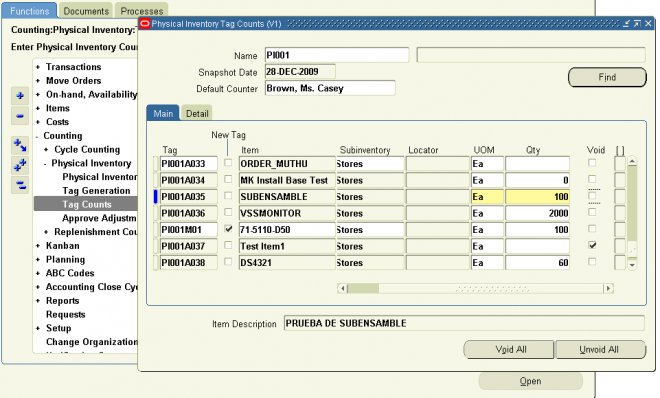

Performing Physical Inventories

Inventory includes the lot numbers of the items to count in your physical inventory when it generates tags. You must assign lot numbers to all items under lot control for which you enter counts in the Physical Inventory Tag Counts window. If there is a difference between the count quantity and the system on–hand quantity, Inventory adjusts the item quantity in that lot.

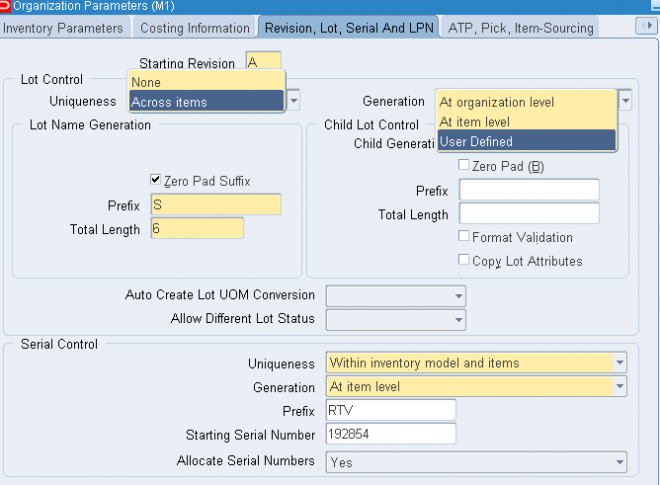

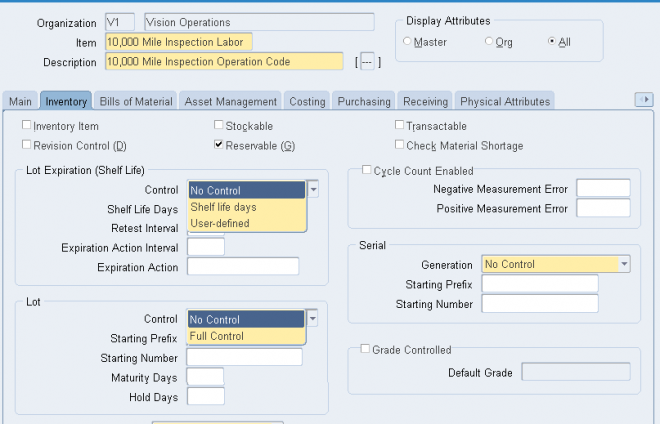

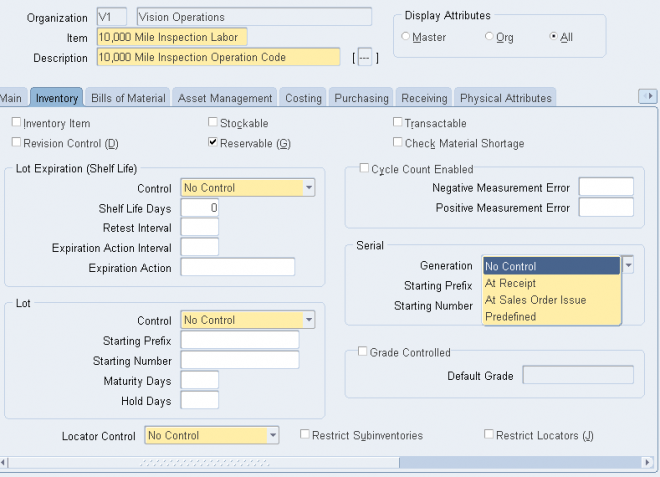

Before using the lot control we need to have the following 3 setups

1. Lot information in inventory tab of item master

http://www.oracleug.com/user-guide/oracle-inventory/inventory-attribute-group

3. Use the Work in Process Parameters window to set up lot control in Oracle Work in Process. You choose the option by which Oracle Work in Process defaults and verifies lot numbers during backflush transactions. You also specify the method by which Oracle Work in Process defaults lot numbers on discrete jobs for lot controlled assemblies.

You can update the disable status and expiration date associated with item lot information.

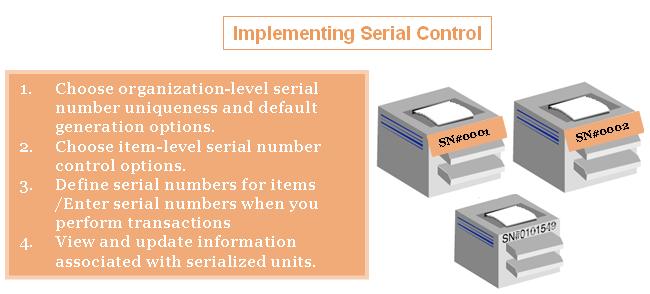

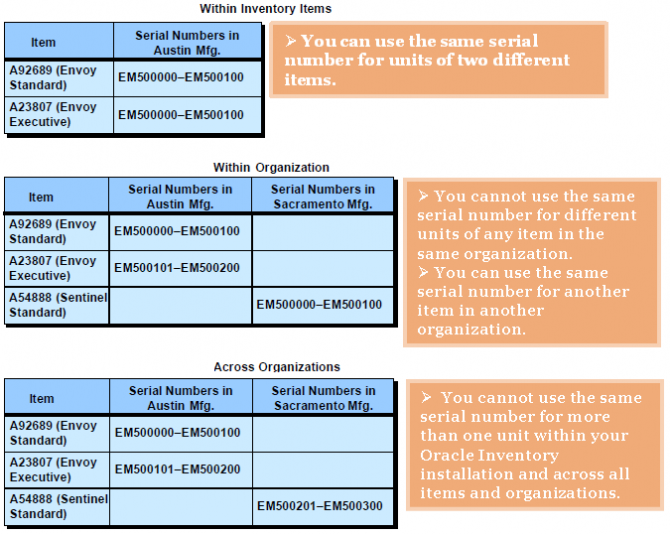

Oracle Inventory provides complete serial number support for inventory transactions. You can enable serial number control for specific items in your inventory. For items under serial number control, you assign unique serial numbers to individual units and

thereafter reference the same serial numbers each time you perform material transactions. This allows you to have tight control over every unit of every item in your inventory. If your item is under dynamic entry At sales order issue, you can only assign serial numbers when you perform a shipment transaction in Oracle Shipping Execution.

Serial Number Validation

Oracle Inventory enables you to perform two optional validations for serial numbers that have been used in Oracle Work in Process. This validation is enabled by setting the profile option, Inventory: Restrict Receipt of Serials to Yes.

• Validation of serialized components:

Enabling the profile option will validate that a given serial number for an item may not be received via purchase order receipt, miscellaneous receipt, or account alias receipt, if that same serial number has been issued to Oracle Work In Process.

• Validation of serialized end–assemblies:

Enabling the profile option will validate that a given serial number for an end assembly item may not be completed into Oracle Inventory for a Discrete Job, Repetitive Schedule, Flow Schedule, and Work Order–less Completion, if that same serial number has a state of, Issued out of stores.

Issuing Material from Inventory

If you issue items with a serial number control type of dynamic entry At inventory receipt or Predefined, you must choose from the list of serialized units that you have already received into inventory. If you issue items with a serial number control type of dynamic entry At sales order issue, you must assign serial numbers when you ship the item

against a sales order.

Assigning Serial Numbers to Assemblies

When you receive into inventory a completed assembly with a serial number control type of dynamic entry At inventory receipt or Predefined, you must assign a serial number in the WIP Completion Transaction window in Oracle Work in Process. You either accept the default serial number or enter another valid one.

Returning Serialized Units to Suppliers

You can return serialized units to the supplier in the Enter Returns and Adjustments window. Oracle Inventory updates the serial number information with the purchase order number and transaction date of the return so that the location of the serialized unit is known.

When you receive replacement units, you can issue new serial numbers. When you receive repaired units, you should reference the original serial numbers so that Oracle Inventory can properly update the existing serial numbers

1. Item master setup

http://www.oracleug.com/user-guide/oracle-inventory/inventory-attribute-group

Generating Serial Numbers

If you specified Predefined as the serial number control type for an item, you must predefine serial numbers for that item.

If you specified entry At inventory receipt or At sales order issue, you can optionally predefine serial numbers for the item. The process of generating serial numbers does not assign serial numbers to units in inventory, it simply reserves specific serial numbers for an item, for later use. When you run the serial generation program if you have the same serial prefix number across organizations, the concurrent program searches across the organizations, and generates serial numbers using the highest start number across the organizations.

Serial Number Assignment

You must assign serial numbers whenever you receive items under serial number control into inventory. If an item is under Predefined control, you can choose from the list of predefined serial numbers for that item. If an item is under dynamic entry At inventory receipt, you can choose from a predefined list of serial numbers or enter any serial number, depending on the uniqueness control for your organization. You can create and assign serial numbers individually or as a range to speed up data entry. If your item is under dynamic entry At sales order issue, you can only assign serial numbers when you perform a shipment transaction in Oracle Shipping Execution.

Once you assign a serial number to an item, the combination of the serial number and the item is an entity known as a serialized unit. From that point on, Oracle Inventory tracks all movements and maintains the following information for each serialized unit:

• Receipt or Ship Date

The date on which you last performed a material transaction for your serialized unit. Material transactions update this

information when you move your serialized unit.

• Serial State

Oracle Inventory assigns one of the following states to your serialized unit: Defined but not used, Resides in inventory, Issued out of inventory, or Resides in intransit.

Status Codes

---------------------

1 Defined but not used

3 Resides in stores

4 Issued out of stores

5 Resides in intransit

6 Pending status

7 Resides in receiving

8 Resides in WIP

You can get a full list of the codes with the following SQL: select

lookup_type,

lookup_code,

meaning

from mfg_lookups

where lookup_type = 'SERIAL_NUM_STATUS'

order by lookup_type, lookup_code

• Location

The organization, subinventory, and locator in which the serialized unit currently resides. Material transactions update

this information when you transfer the serialized unit.

• Revision level

The revision of the item when you assign the serial number to the unit.

• Lot number

During material transactions, you first specify the lot number and then the serial number. Oracle Inventory tracks the lot from which a specific serialized unit originates.

You can view location, job and state information, as well as update supplier information associated with your serialized units.

1. Navigate to the Serial Numbers window. The Find Serials window appears.

2. Enter search criteria. If you do not enter criteria, a query for all serial numbers is performed.

3. Choose the Find button to display the serial number and item information in the Serial Numbers window.

You must set certain controls and options before performing inventory transactions. These include:

Setting transaction profile options:

Oracle Inventory provides you with the following transaction processing profiles:

• Enter Replenishment Count

• Inter–Organization Transfer

• Miscellaneous Issue and Receipt

• Transaction Processing Mode

• Transfer Between Subinventories

• Update Average Cost

• Server Side On–line Processing

• Allow Expense to Asset Transfer

• Project Miscellaneous Transaction Expenditure Type

• RPC Timeout

• Restrict Receipt of Serials

• Transaction Date Validation

• Use New Trx Manager for Processing

• Override negative for Blackflush

• Quantity Tree Timeout for Lock

• Maximum Number of Quantity Trees

• Cycle Count Approvals

• Cycle Count Entries

Transaction Processing Mode

You can set processing control globally for all transactions or you can choose different options for each type of transaction. You establish the method of transaction processing by choosing one of the following options when you set up your TP:INV Transaction Processing Mode profile:

On–line processing Processes transactions while you wait and returns control to you once it finishes.

Background processing Returns control immediately to you. With this option, Oracle Inventory processes transactions

on a periodic basis via the Inventory Transaction Manager.

Immediate concurrent processing Spawns a concurrent process when you commit the transaction and returns control immediately to you, allowing you to continue working.

Form level processing Processes transactions using the processing control option you choose for that particular type of transaction. You must also set the Inventory profile options for Inter–Organization Transfer, Miscellaneous Issue and Receipt,

Receive Customer Return, Return to Customer, and Transfer Between Subinventories. If you are using Oracle Work–in–Process, you must set the WIP profile options Completion Material Processing, Completion Transaction Form, Material Transaction Form, Move Transaction, Operation Backflush Setup, and Shop Floor Processing.

If you choose Form level processing for the Transaction Processing Mode profile you can set up different processing controls for each type of transaction.

On–line Processing If you use On–line processing, you can choose whether transactions are processed on the server or client side by setting the Server Side On–line Processing profile. The default value is server side processing.

Inventory Remote Procedure Manager Server side on–line processing uses the Inventory Remote Procedure Manager to allow a transaction initiated on the client to process on the server. System managers maintain the Remote Procedure Manager.

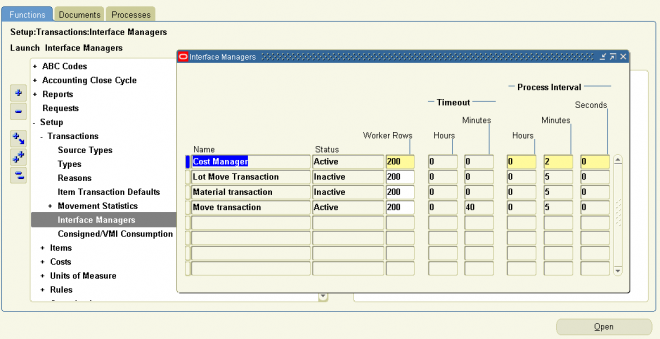

Launching Transaction Managers

The transaction managers execute the following processes:

material transaction,

move transaction,

resource cost transaction,

material cost transaction,

demand reservation &

remote procedure call.

These run at periodic intervals you specify until you delete them with the concurrent manager. They control the number of transaction workers, processing intervals, and number of transactions processed by each worker during each interval.

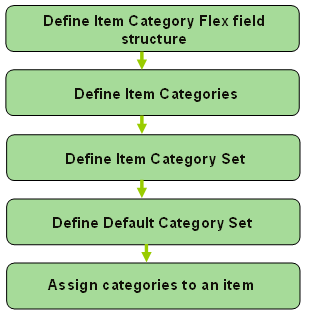

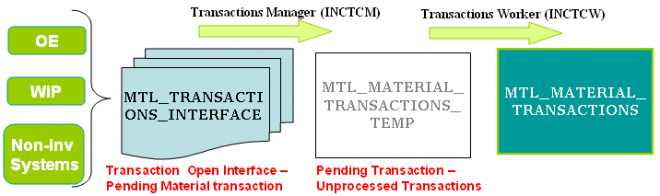

The relationship between transaction source type, transaction action and transaction type is shown in below picture.

Transaction source type = Purchase Order

Transaction source = Purchase Order Number

Transaction Action = Receipt

Transaction type = PO Receipt

A transaction action is a generic type of material movement or cost update with no specificity regarding the source of the transaction. Along with a transaction source type, a transaction action identifies a transaction type. Oracle Inventory provides the following transaction actions:

• Issue from stores

• Subinventory transfer

• Direct organization transfer

• Cycle count adjustment

• Physical inventory adjustment

• Intransit receipt

• Intransit shipment

• Cost update

• Receipt into stores

• Delivery adjustments

• WIP assembly scrap

• Assembly completion

• Assembly return

• Negative component issue

• Negative component return

• Staging Transfer

A transaction type is the combination of a transaction source type and a transaction action. It is used to classify a particular transaction for reporting and querying purposes. Oracle Inventory also uses transaction types to identify certain transactions to include in historical usage calculations for ABC analysis or forecasting. The following table presents predefined transaction types:

Use the Transaction Types window to define additional transaction types to customize transaction entry. A user–defined transaction type is a combination of a user–defined transaction source type and a predefined transaction action. For example, if you frequently donate items to charity, you might want to define a transaction source type called ”Charity” and a transaction type called ”Issue to Charity”. In this case, the transaction action would be Issue from Stores. You would then use the Miscellaneous Transactions window to actually issue an item to charity, using the ”Issue to Charity” transaction type. You would also specify the actual charity to which you are issuing, such as Goodwill, and the expense account that specifies the source (Goodwill).

You define transaction types by combining transaction actions and transaction source types. You define transaction source types in the Transaction Source Types window. Oracle Inventory provides the list of transaction actions.

You must specify a transaction type when you perform a miscellaneous receipt or issue, a subinventory transfer, a WIP transaction, or an inter–organization transfer.

A transaction reason is a standard means of classifying or explaining the reason for a transaction. Transaction reasons can be used in all transaction forms.

You can use these standard transaction reasons with any type of material transaction. Oracle Inventory provides transaction reporting and inquiring capabilities by transaction reason.

In the reason type from the list of values. The available choices are as follows:

• Load

• Drop

• Receiving

• Replenishment

• Cycle Count

• Shipping

• Update Status

• QA Update Status

Note: The Replenishment reason type is disabled.

If you selected Picking as the Reason Type, select a Reason Context from the list of values. The available choices are as follows:

• Curtail Pick: End the pick after picking a few LPNs or Lots and load the contents.

• LPN Exception: Pick partial quantity of the scanned fully consumable LPN.

• Pick None: End the pick without picking anything.

• Pick Over: Pick more than the requested quantity.

• Pick Partial: Split the pick and allow confirmation of less than the requested quantity. You must still pick the entire quantity, but can pick in stages.

• Pick Short: Specify a quantity less than the requested quantity, and back order the rest of the required quantity.

• Change Source Locator: Change the location from which the material is picked.

• Change UOM: Change the transaction unit of measure for the task.

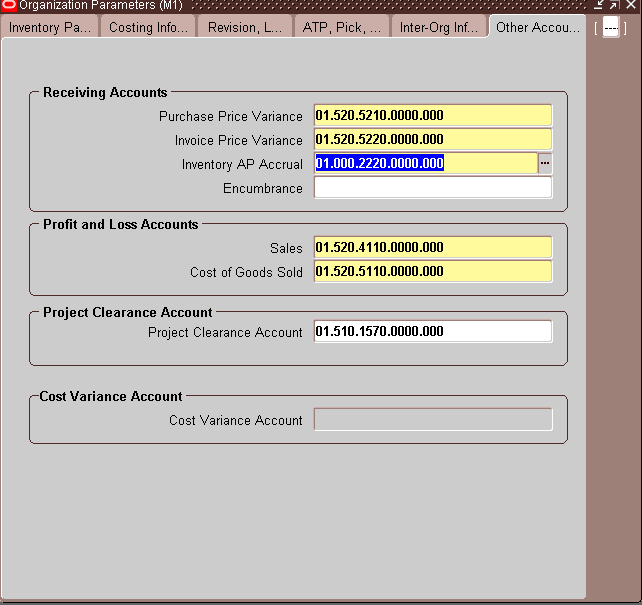

Use the Inter–Organization Shipping Network window to define accounting information and the relationships that exist between shipping and destination organizations. You can specify whether an organization is a shipping organization, a destination organization, or both.

1. From-TO organization

8. Intransit lead time

Select Shipping Methods on the Tools menu to open the Inter–org Shipping Methods window.

Enter the shipping method for which you want to associate an intransit lead time for the displayed from and to organizations and enter the intransit lead time in days.

Use the Intercompany Relations window to define, query, and update intercompany relations between two operating units in a multi–organization environment. These operating units are either the shipping organization and the selling organization, or the receiving and purchasing organization.

When a sales order is entered in an operating unit, the shipping organization is often part of a separate operating unit, belonging to a separate set of books. Once the sales order is shipped to the customer, the inventory asset account for the shipping organization is credited and the cost of goods sold account is debited. On the other hand, sales revenue must be recognized in the order entry organization. If the two organizations belong to different operating units, the system must perform accounting distributions to record the intercompany revenue, receivable, and payable entries.

Oracle Inventory and Oracle Receivables must be installed before you can define intercompany relations. If Oracle Payables is not installed, the fields in the AP Invoicing for Selling region are not required.

Oracle Inventory, with Oracle Order Management, Oracle Purchasing, and Oracle Work in Process, provides you with a complete set of transactions and reports for maintaining inventory control. This allows you to control the flow of material from the time you receive items to the time you ship finished goods to the customer.

Inventory transactions and on hand balance supports decimal precision to 5 digits after the decimal point. Oracle Work in Process supports decimal precision to 6 digits. Other Oracle Applications support different decimal precision. As a result of the decimal precision mismatch, transactions another Oracle Application passes may be rounded when processed by Inventory. If the transaction quantity is rounded to zero, Inventory does not process the transaction. It is therefore suggested that the base unit of measure for an item is set up such that transaction quantities in the base unit of measure not require greater than 5 digits of decimal precision.

You can define multiple inventories, warehouses, and manufacturing facilities as distinct organizations. With Oracle Inventory you can perform inter–organization transfers as direct or intransit shipments.

Inter-Org transfers can be done within or accross operating units but you can not generate intercompany invoice with inter-org transfer. Intercompany invoicing is possible for inter-org transfers of type ‘In-transit’ only through ‘Internal sales Orders’. No intercompany invoicing is possible if you perform org transfers between two inventory orgs belonging two different operating units without ‘internal sales Orders’. Also note that intercompany invoice cannot be raised for inter-org transfers of type ‘Direct Transfer’ through Internal sales Orders.

You can use a direct inter–organization transfer to move inventory directly from a shipping organization to a destination organization. The validity of a transfer transaction depends on the controls you have defined in both the shipping and destination organizations for the items you want to transfer. For example, you can transfer item A from organization X to organization Y, even though item A is under lot control only in organization X (you can specify the lot numbers for item A in organization X during the transfer transaction). However, you cannot transfer item B from organization X to organization Y if item B is under lot control only in organization Y (you cannot specify lot numbers for item B in the destination organization because you are performing a

direct transfer).

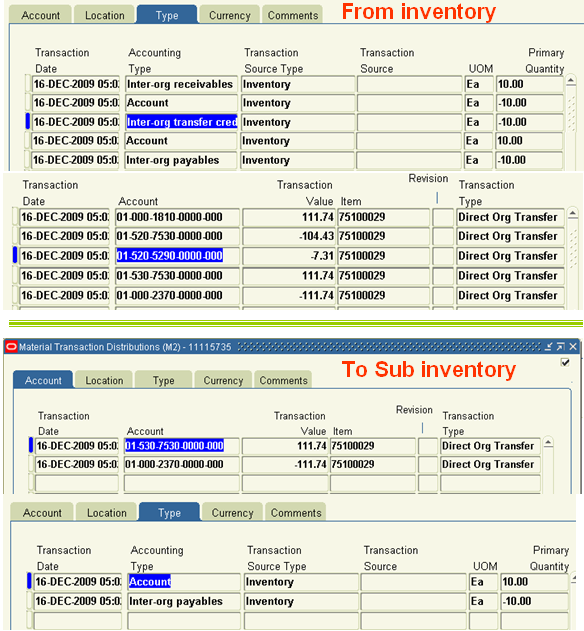

The following tables present direct, inter–organization transfers.(As given in oracle user guide)

If destination is Asset/Serial controlled/Lot controlled/ Revision Controlled then the source needs to be Asset/Serial controlled/Lot controlled/ Revision Controlled

You usually transfer material to intransit inventory when transportation time is significant. When you perform the transfer transaction, you do not need to specify the delivery location. You only need to enter the subinventory you are shipping from, a shipment number, the freight information, and, depending on the inter–organization transfer charge that applies between the organizations, a percentage of the transaction value or a discrete amount that Oracle Inventory uses to compute transfer charges.

If the FOB point is set to Receipt in the Shipping Networks window, the destination organization owns the shipment when they receive it. If it is set to Shipment, the destination organization owns the shipment when the shipping organization ships it, and while it is intransit.

While your shipment is intransit, you can update shipping information such as the freight carrier or arrival date in the Maintain Shipments window.

At the time of shipment, you must define your receiving parameters for the destination organization. You can receive and deliver your shipment in a single transaction or you can receive and store your shipment at the receiving dock.

The validity of a transfer transaction depends on the controls you have defined in both the shipping and destination organizations for the items you want to transfer. For example, you can transfer item A from organization X to organization Y, even though item A is under lot control only in organization X (you can specify the lot numbers for item A in organization X during the transfer transaction). You can also transfer item B from organization X to organization Y if item B is under lot control only in organization Y (you can specify lot numbers for item B in the destination organization when you perform the receiving transaction).

1. The following tables present inter–organization transfers via intransit inventory.

2. In case of inter organization transfer via Intransit we required to put the shipment number

After completing the inter org transfer, go to the receiving form of the 'to org' and receive the shipment with the shipment number.

There are certain restrictions and expected behaviors when transferring items between organizations where the serial control in the source and destination organizations are different. The following tables explain the expected results.

You can transfer material within your current organization between subinventories, or between two locators within the same subinventory. You can transfer from asset to expense subinventories, as well as from tracked to non–tracked subinventories. If an item has a restricted list of subinventories, you can only transfer material from and to subinventories in that list. Oracle Inventory allows you to use user–defined transaction types when performing a subinventory transfer.

To do a subinventory transfer from expense to asset subinventory set the profile option INV: Allow Expense to Asset Transfer to "Yes."

If it has not been set it to "Yes," it is possible to issue from an asset to an expense subinventory, but issue from an expense to asset subinventory is not possible. Oracle Inventory expects the consumption of material at the expense location. If you return an asset item to an expense subinventory, you must be first issue it from the expense subinventory using the Miscellaneous

Transaction form and transfer it to the subinventory expense account. Then, no accounting occurs and you only transfer quantities. To receive the asset item back to the asset subinventory, perform the Miscellaneous Transaction account receipt using the same expense account as the expense subinventory.

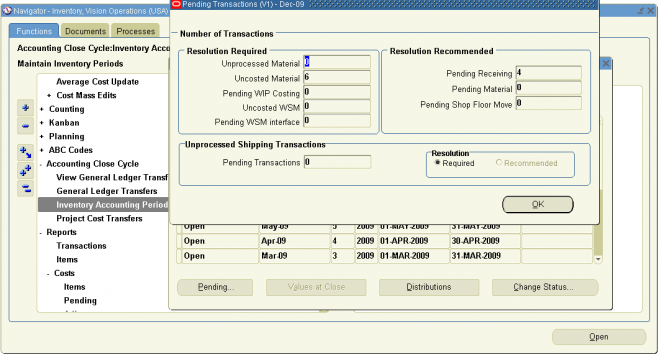

For receiving an ASSET item back, you use the Miscellaneous Transaction instead of the subinventory transfer.