Depot Repair

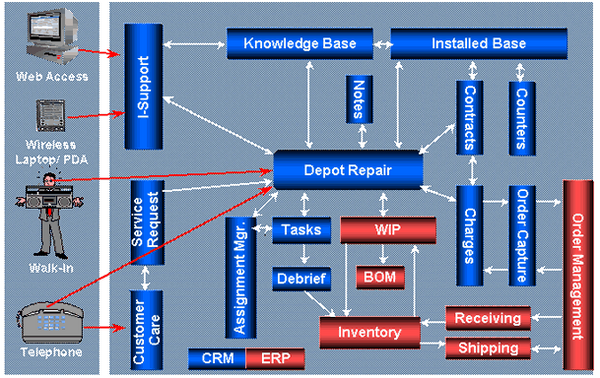

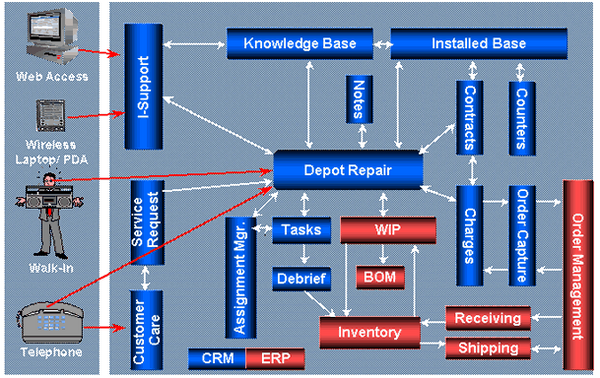

Oracle Depot Repair is part of the Oracle E-Business Suite and offers an enterprise-wide solution for managing depot repair processing. It targets the repair business market from simple, quick repairs to routine maintenance. Oracle Depot Repair integrates with other Oracle E-Business Suite modules to provide an integrated comprehensive solution for the repair business sector.

The depot repair process includes the return of broken and serviceable items, their diagnoses and repair job estimates, customer approvals and repairs management, and subsequent return of items to customers. You use the collection of charges for materials, labor, and expenses for the repairs to invoice the customer.

The depot repair process also includes the processing of item refurbishments, where the items either belong to an internal party, or the items are received from a field service warehouse and then returned to the warehouse after repair.

Customers expect quick and seamless repair processing. Oracle Depot Repair provides end-to-end repair management functionality for service organizations that are committed to delivering a total service solution.

Oracle Depot Repair enables service organizations to meet customer expectations, and draw maximum benefit by improving service readiness.

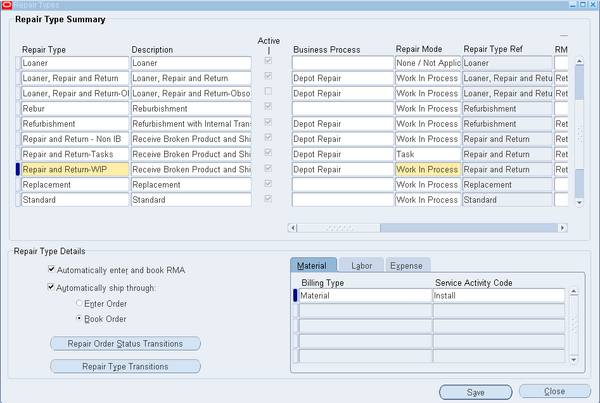

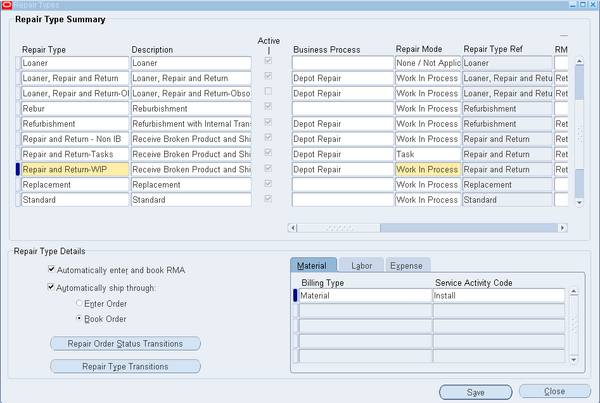

2.1 Repair Type

Oracle Depot Repair provides the similar functionalities as order type (line type) in order management or transaction type in account receivables. Repair Types help to classify the Repair Order and determine the repair management processes and logistics to fulfill the repair process. These repair types enable service providers to be more efficient in managing the repair through process automation.

Oracle Depot Repair supports the following Repair Types:

- Loaner

- Repair and Return

- Loaner, Repair and Return

- Exchange

- Advance Exchange

- Replacement

- Standard

- Refurbishment

Loaner

Use this Repair Type when the service depot sends an item to the customer solely for the purpose of renting. This Repair Type requires a Sales Order to ship the loaner item to the customer and to create an invoice, and an RMA order to track the return of the loaner item. A deposit and return due date may be a requirement. The customer has no expectation of repairs.

Repair and Return

Use this Repair Type when a customer returns the broken or damaged item to the service depot for repair. After completion of the repair, you return the repaired item to the customer. This Repair Type requires:

A return materials authorization (RMA), or Return line, to receive the customer's broken or damaged item. A Sales Order, or Ship line, to ship the repaired item and invoice the customer.

Loaner, Repair and Return

This Repair Type combines two Repair Types, the Repair and Return, with the Loaner. The loaner concept indicates that service depot sends the customer the loaner before the receipt of the customer's broken or damaged item. To track the shipping and return of both the loaner and the broken or damaged item, the system creates four charge lines. This Repair Type requires two RMA Orders and two Sales Orders. Use this Repair Type when a customer uptime is critical.

Exchange

This Repair Type represents a scenario when the service depot sends an exchange item to the customer after receiving the customer's broken or damaged item. The Exchange Repair Type assumes that the repaired item does not return to the customer. The system can generate an internal Repair Order for the returned item, but there is not necessarily an association between the repaired item and the original exchange item.

Advance Exchange

This Repair Type is the same as the Exchange Repair Type except that the service depot can send the item to the customer before the service organization receives the customer's broken item.

Replacement Repair Type

A Replacement Repair Type refers to a scenario when the service depot sends an item to the customer without expecting a return. In this scenario, the service provider sends the customer an item to replace the customer's item. The service organization can:

Link the replacement item to the original item in the Installed Base.

Change the status of the replaced item to indicate that it is out of service and that the new item has replaced it.

Standard

Use this Repair Type when the service agent is uncertain about the customer's needs. This Repair Type is flexible however, and requires the manual creation of RMAs and Sales Orders.

Refurbishment

A Repair Order and its associated Service Request can be created in the Spares Management of Oracle Field Service as a result of a demand for refurbishment or replenishment. The Repair Order has a Repair Type of Refurbishment, and has two transaction lines, Move In and Move Out.

The Move In line tracks the shipment of the defective item from Spares Management, and its reception into the depot. The Move Out line processes the shipment of the repaired item back to Spares Management.

The processing of Move In and Move Out lines leverages existing Internal Order and Internal Requisition functionality. From the depot's perspective, defective items are received via the Internal Requisition, and usable/repaired items are shipped via the Internal Order.

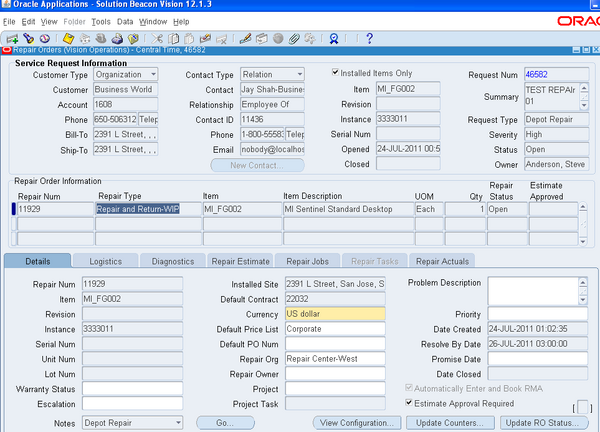

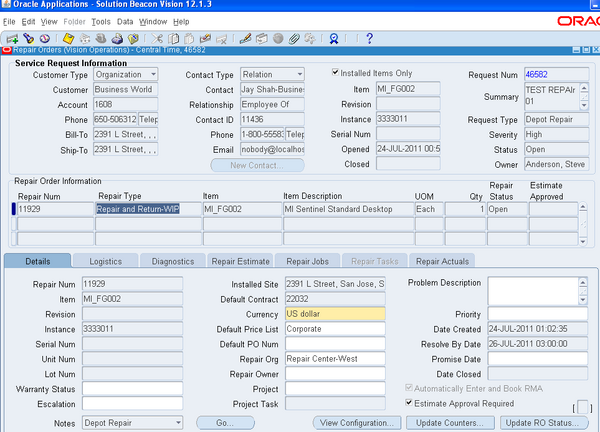

Overview of Depot Repair

At the core of Oracle Depot Repair is the Depot Repair Workbench that provides service agents with instant access to customer and Repair Order information. You can access a number of tabs from the Depot Repair Workbench. Some tabs show information about the customer, the Service Request, and the service history of the item. Other tabs let you process transactions, such as:

• Receipt or shipment.

• Creation and processing of Repair Jobs and tasks.

The Depot Repair Workbench also provide access to a knowledge base through Oracle Knowledge Management.

Navigation : Depot Repair > Repair Orders

The title of the main window in Oracle Depot Repair is Repair Orders. As most of the Oracle Depot Repair user operations start in this window, it is generally referred to as the Depot Repair Workbench.

In the Depot Repair Workbench you can perform all service depot repair functions, including Repair Order creation, status monitoring, receiving, and shipping. From the Depot Repair Workbench, you can create Repair Orders to track the activities on customer or vendor items returned to service depot repair, for repair, upgrade, or overhaul.

The Depot Repair Workbench provides integration with Oracle E-Business Application Suite modules and components, such as Notes, Charges, Knowledge Management, Install Base, Work in Process (WIP), Bills of Material (BOM), General Ledger, Inventory, Shipping, and Receiving.

Service organizations can start their service depot business process from the Depot Repair Workbench. When a service agent enters the customer and item information, the Depot Repair Workbench automatically validates the customer and item in the Install Base.

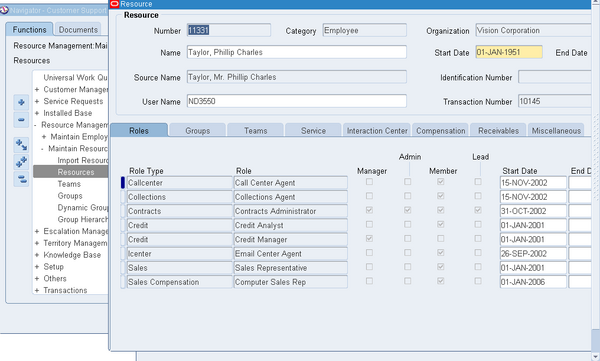

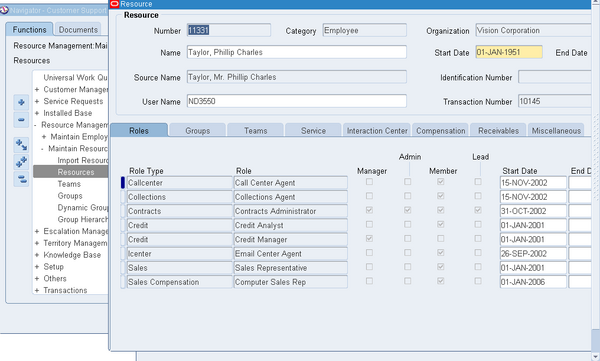

User-to-resource link

Select one of the users for which the issue happens and reset the link.

1. Log on as Customer Support Responsibility

2. Select Resources > Maintain Resources

3. Open the Resource Form

4. Find the Resource using the name and category

5. Navigate to Resource Details

6. Locate the field called User Name.

If there are no values in that field click the LOV, select the user name and save the record.

If there is a user name, clear the field and save the record.

Then click the LOV again and select the correct user name.

7. Log out of the application and log back in as the user that was just set up.

8. Test again and replicate as necessary to other environments.

Depot Repair Setups

Setting up Oracle Depot Repair includes setting up related Oracle applications, such as Oracle Inventory and Oracle Installed Base. In setting up these applications, you might only need to make Depot Repair specific modifications to existing data, like existing items. Check with your implementation team to determine which setup requirements have already been fulfilled.

Resource Creation

Determine the resources that have to be created in the system. All Call Center Agents, Service Administrators, Receipt Administrators, Service Technicians, Depot Managers, Field Service Agents, and other employees who will be using Oracle Depot Repair must be created as resources

WIP and Task Modes

Determine the complexity of the repair management processes required by your organization. Either Oracle WIP or the Task Manager (in Oracle Common Application Components) can be used to manage the repair process. WIP mode is recommended for use when the Repair Jobs require series of sequential steps, and materials management. Task mode is recommended for use when the repairs require minimal steps that are not necessarily completed in sequence. To the user, both of these processes are managed via separate tabs in the user interface.

The Oracle Depot Repair application supports the use of both WIP and Task modes for repair management. However, it is advisable to use only one mode to enhance the user experience

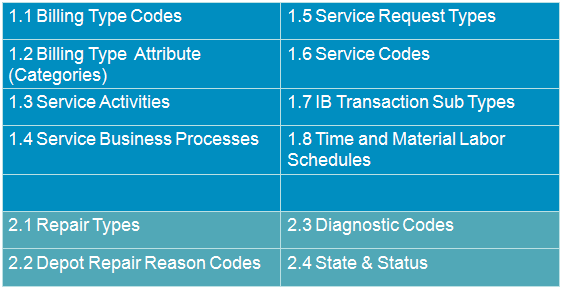

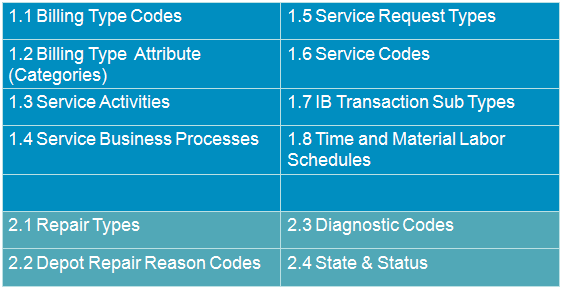

1.1 Billing Type Codes

Every item to be processed using Charges must be set up in Inventory as a Material, Labor, or Expense (MLE) item. This means every item in Oracle Applications that may need repair must be set up as a Charges MLE item.

Billing Categories classify Billing Types into Material, Labor, and Expense. Each serviceable item in Inventory is classified using Billing Type Codes associated to a Billing Category.

A Service Activity Code is a type of action to be performed, for example, replace, return, install, drain, fill. The combination of Billing Type and Service Activity defines the Order Type for a given operating unit. It also provides the basis upon which discounts for a Service Contract can be applied.

Charges is a module of Oracle TeleService. Setting up Charges for all service-related processing consists of steps that serves a variety of Oracle applications, including Oracle Depot Repair.

Setting up Oracle Charges for Depot Repair processing includes the following setups :

- Defining Billing Type Codes

- Mapping Billing Type Codes to Billing Categories

- Defining Service Activities and Billing Types

- Defining Service Business Processes

- Defining Installed Base Transaction Sub Types

- Setting Up Time and Material Labor Schedules

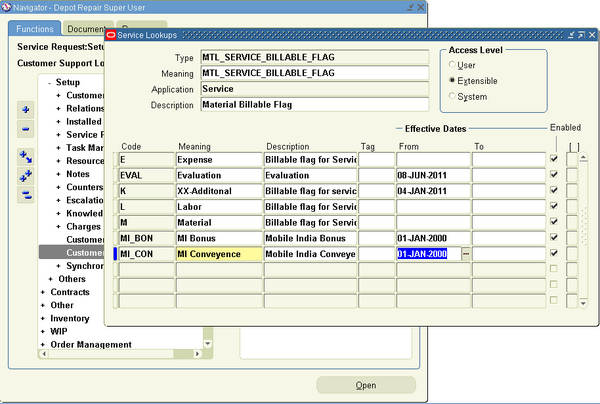

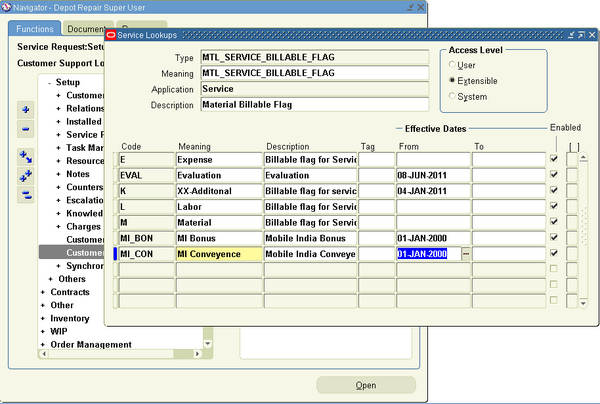

To define Transaction Billing Type Codes:

1. From the Navigator, use the following path to open the Oracle Service Lookups window:

Service Request > Setup > Customer Support Lookups.

2. Query up the Lookup Type MTL_SERVICE_BILLABLE_FLAG.

3. Add the new required Billing Type Codes. You can use the online help for more information.

The seeded Billing Type Codes are M, L, and E.

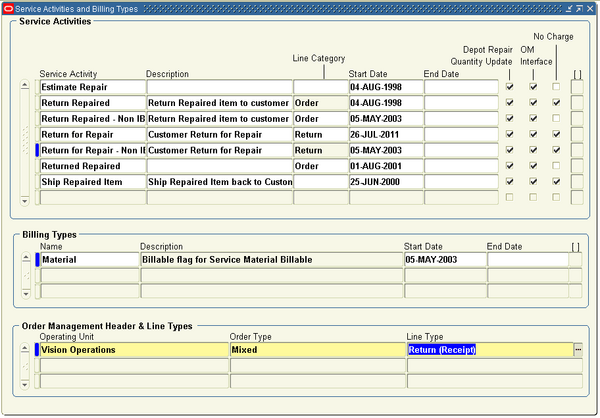

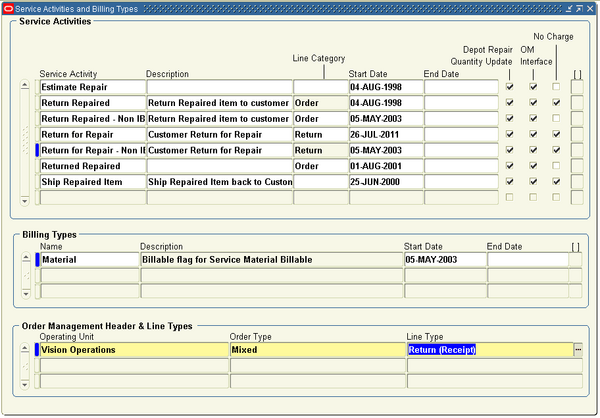

1.3 Service Activities

A Service Activity is a business operation, such as Replacement or Return for Repair. Each Service Activity is classified as either an Order or a Return - this is specified by its Line Category.

A Service Activity has a one to many relationship with Service Activity Billing Type. A Service Activity Billing Type, for example, Advanced Exchange: Material, is an intersection between Service Activity Advanced Exchange and Billing Type Material.

The Service Activity Billing Type is linked to an Oracle Order Management Order Type and Line Type for each operating unit. Oracle Order Management Order and Line Types are associated with Service Activities that are assigned to Repair Types in Oracle Depot Repair. When a user chooses a Repair Type, these Order and Line Types determine the processing of charge lines (RMA, Ship, Estimate) for a Repair Order.

Oracle Order Management provides seeded Workflow process definitions for both orders and lines. It enables you to define both order header and order line Service Activities. The seeded Service Activities that Order Management provides are, however, not mapped by default.

A Service Activity is operating unit-specific. The Line Category is set at transaction level to prevent the use of a single Service Activity as an order in one operating unit and a return in another.

The Order Management Header & Line Types region is used to specify the organization, header type, and line type - in the Operating Unit, Order Type, and Line Type fields respectively - to be used when a charge line is submitted to Order Management. These values are used to retrieve an Order Management header type and line type from the setup while submitting the order.

1. In the Related Billing Types region, select the appropriate Billing Type to be associated with the Service Activity you are creating.

2. Select the Depot Repair Quantity Update checkbox to update the depot inventory. Only Service Activities with Depot Repair Quantity Update check box selected will be displayed in the Service Activity list of values in the Logistics tab in the Repair Types window.

3. Leave the OM Interface check box selected (the default value). This setting means the customer can be billed for charges for this activity.

4. Select the No Charge flag checkbox if you do not want to charge the customer for this Service Activity.

Please note that an estimate or actuals line is discounted based on the contract associated with the Repair Order only if the Service Activity Billing Type of the estimate or actuals line is also set up for the contract. The Service Activity Billing Type of the estimate or actuals line is determined based on the Repair Type for the Repair Order, and the Billing Type for the estimate or actuals line item.

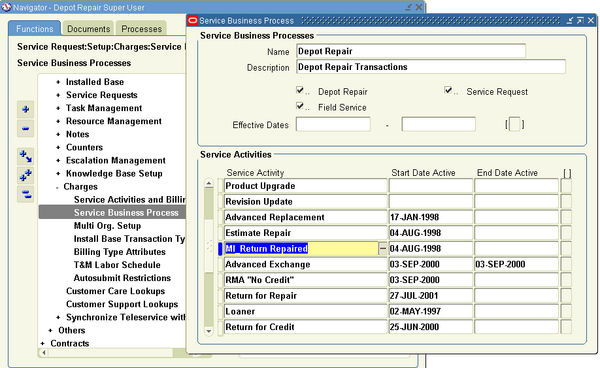

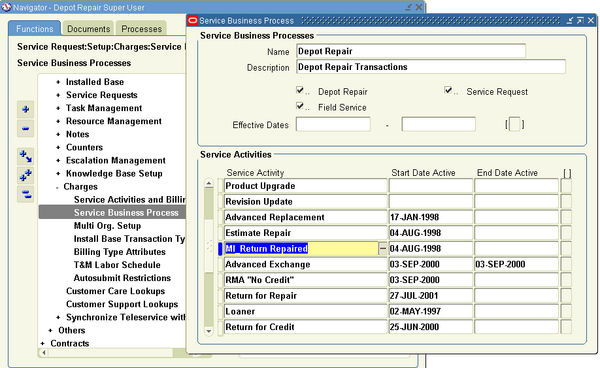

1.4 Service Business Processes

A Business Process is a group of Service Activities created with a view to restricting Service Activity availability. A Business Process supports the charge lines that the line of business in your organization can utilize, such as, Depot Repair.

Use the Service Business Process window to define your Business Process and associate Service Activities with it. Ensure that the Depot Repair check box is selected when setting up the Business Process. For a particular Business Process, the selected flag check boxes indicate the modules (Service Request, Field Service, Depot Repair) in which this Business Process can be used.

To Define Service Business Processes:

1. Open the Service Business Process window using the following navigation path:

Service Request > Setup > Charges > Service Business Process.

2. Enter the appropriate value in the Name and Description fields.

3. Select the Depot Repair check box.

You can also optionally select any of the other check boxes for the applications (Service Request, Field Service) where you want this Business Process to be visible.

4. Enter the Effective Dates for the Business Process if you want the Business Process to be used only for a limited time.

5. In the Service Activities region, select the Service Activity you want to associate with the Business Process.

6. Save your work, and exit the Service Business Process window.

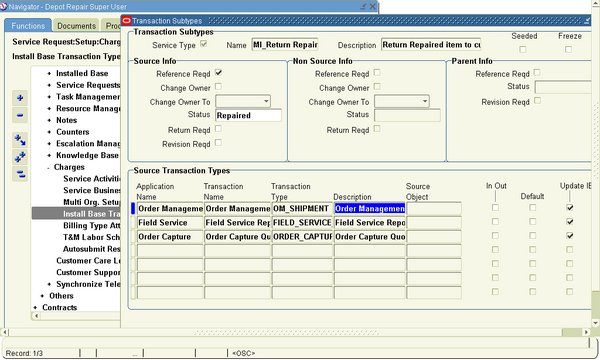

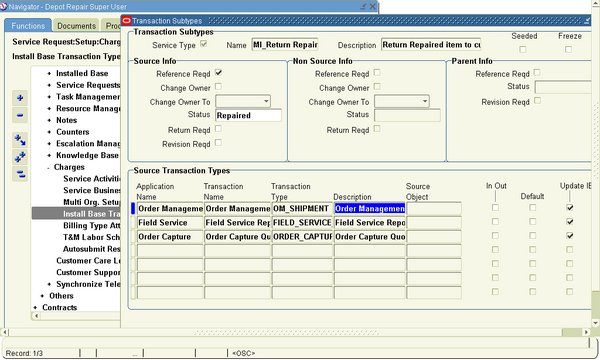

1.7 IB Transaction Sub Types

Each Service Activity that is required to process an Installed Base trackable item must have an Installed Base Transaction Sub Type with the same name as the Service Activity. For example, for the Service Activity named Return for Repair, we define the corresponding Transaction Sub Type with the name Return for Repair.

For items that are not Installed Base trackable, the Service Activities associated with the Repair Type should not have Installed Base Transaction Sub Types defined. Hence you need to have separate

Repair Types and Service Activities defined for Installed Base trackable items and for non-trackable items.

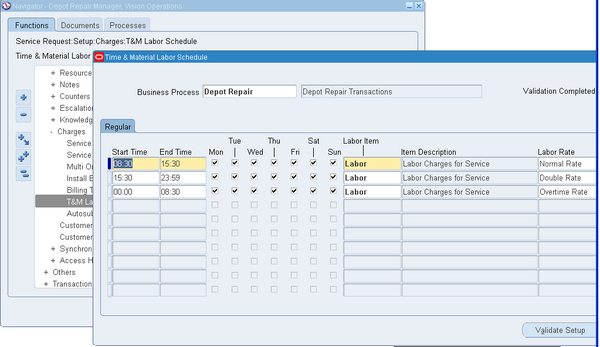

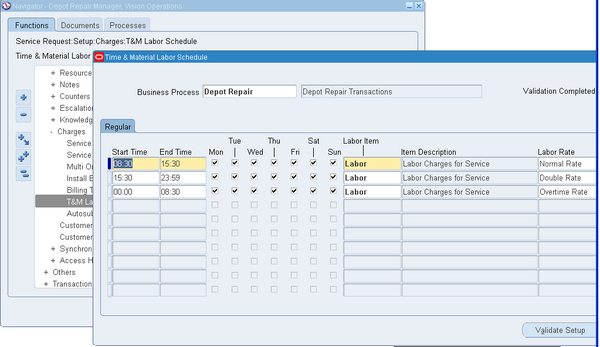

1.8 Time and Material Labor Schedules

Use the Time & Material Labor Schedule window to set up schedules for the Depot

Repair Business Process. This is required to process any labor transaction in the Debrief

form accessed from the Repair Tasks tab in the Repair Orders form.

From the Navigator, use the following path to access the Time & Material Labor

Schedule window:

Service Request > Setup > Charges > T&M Labor Schedule.