Consignment Inventory

Consignment Inventory is inventory that is in the possession of the customer, but is still owned by the supplier. In other words, the supplier places some of his inventory in his customer’s possession (in their store or warehouse) and allows them to sell or consume directly from his stock. The customer purchases the inventory only after he has resold or consumed it. The key benefit to the customer should be obvious; he does not have to tie up his capital in inventory. This does not mean that there are no inventory carrying costs for the customer; he does still incur costs related to storing and managing the inventory.

Consignment Inventory is inventory that is in the possession of the customer, but is still owned by the supplier. In other words, the supplier places some of his inventory in his customer’s possession (in their store or warehouse) and allows them to sell or consume directly from his stock. The customer purchases the inventory only after he has resold or consumed it. The key benefit to the customer should be obvious; he does not have to tie up his capital in inventory. This does not mean that there are no inventory carrying costs for the customer; he does still incur costs related to storing and managing the inventory.

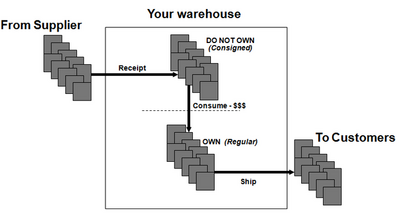

From the "Consigned inventory from supplier" User's Guide: Consigned inventory from supplier exists when inventory is in the possession of one party (a dealer, agent, distributor, and so on), but remains the property of another party(such as the manufacturer or primary contractor) by mutual agreement. Consigned inventory from Supplier refers to one type of consigned inventory practice where you receive and maintain goods belonging to one or more of your suppliers. Both suppliers and customers benefit through a consigned inventory strategy:

- Suppliers can compete on the basis of availability and delivery when finished goods are at the customer site, particularly when lead times are lengthy.

- Holding material on consignment reduces the lead time for items that might be required to fill sales orders.

- Customers experience increased inventory turns thus, reducing funds invested in inventory. Financial resources are free until customer commitments are ensured, or items are used in production.

Consigned VMI with Customers Is defined as the process that allows you to manage inventory at your customer sites (monitoring of on-hand, as well as the replenishment), and to operate a consigned inventory (pay-on-use) scenario where the material ownership remains with you until it is consumed by the customer. Traditionally, this process is highly laborious and transactional oriented and provides little visibility into the customer inventory and demand position. It is prone to stock outs and increased expediting costs. What you want to do is move to a more automated planning and execution process.

Benefits of consignment include:

Supplier:

1. Does not need to store material 2. Reduced delivery costs, less rush orders, transportation efficiencies 3. Material closer to point of sale Buyer

1. Reduced lead time 2. Reduced funds invested 3. Easier access to material

Consignment Inventory Buyer Prospective (With Supplier)

Currently, Purchasing does not allow encumbrance and consignment to be active at the same time (they are mutually exclusive in the same Operating Unit)

Setups

1. Item : Nothing special here, just make sure that the item is stockable and purchasable.

2. Define and assign a Sourcing Rule for this Item :

Create a Sourcing Rule specifying Both a Supplier and Supplier Site. Make sure the supplier site is a valid purchasing site. Assign the sourcing rule to the Default assignment set (as specified in MRP: Default Sourcing Assignment Set).

3. Create a Blanket Agreement (ASL source document)

Create a normal Blanket Agreement specifying pricing for this Item as appropriate.

Take care that the supplier and supplier site used here must be the same as those in the sourcing rule and ASL.

4. Create ASL entry

Take care that you MUST specify a supplier site here otherwise you will not be able to enable consignment for this ASL entry. Also ensure that the supplier and supplier site used here are the same as those in the Blanket Agreement and Sourcing Rule.

Specify the Blanket Agreement number.

If you are unable to select the Blanket Agreement you have created here please check for the following :

A – The Blanket Agreement is not approved

B – The Supplier/Supplier Site combination on the Blanket Agreement is not the same as on the ASL entry

C – The Item on the Blanket Agreement is not the same as on the ASL entry

Now click on the Inventory tab. This is the part of the setup that is different from automatic sourcing.

Make sure to check the ‘Consigned from Supplier’ check box. This is the most important part of the setup.

Business Cycle

1. Create a standard PO

Even though we have created a Blanket Agreement as the source document, consignment requires a PO (and not a Release) to begin the cycle.

Obviously the PO should contain the same Item, Supplier and Supplier Site as those in the Blanket Agreement, Sourcing Rule and ASL.

Approve the PO. Please note that no accounting is expected at this point since encumbrance is disabled (Encumbrance is not compatible with consignment).

2. Receive the Goods

Receive the goods in the destination inventory.

Save the receipt. The goods are now in the specified subinventory. If this was a normal PO, the appropriate accounting transaction would have been created

(Dr Receiving Area account / Cr Inventory AP Accrual account). However, since this is a consigned PO, we do not expect any accounting transaction to have been created.

we can receive the material w/o creating a standard PO and bu just doing a misc. receipt. The owning party should be selected as the supplier.

3. Convert consigned goods to regular goods

Consigned stock is automatically converted to regular stock when certain inventory transactions take place (e.g. shipping), however there is an inventory process that allows consigned stock to be transferred to regular stock (and vice versa). Once consigned stock has been converted to regular stock, the receipt accounting transactions are generated.

To transfer consigned stock to regular stock navigate to Inventory Responsibility->Transactions->Consigned Transactions

Once you specify the Item and Subinventory, the system will check the available and on-hand consigned stock in this subinventory. If you have received the goods correctly then there will be consigned stock which is eligible for transfer to regular stock.

Once this transaction is saved, the item is now regular stock. If you try to create a new transaction the consigned stock will have decreased and if there is no consigned stock left, you will not be able to complete this transaction. Let us now check that the appropriate accounting transaction has been created.

Navigate to Inventory Responsibility->Transactions->Material Transactions form and query the Item.

Goods can also be automatically transferred to regular stock through other means.

From the Oracle Inventory Consigned Inventory from Supplier Process Guide :

The system automatically generates a Transfer to Regular transaction whenever consumption takes place. Consumption transactions are performed either explicitly or implicitly. Explicit consumption is performed whenever the user specifies the external owning party (the consignor) whose goods will be transferred to the internal organization. Explicit consumption is performed by using the consigned transactions window and performing a transfer to regular transaction, or for example, by performing a miscellaneous issue and indicating the owning party in the transaction line. Implicit consumption refers to any type of consumption in which the system automatically determines that consumption is necessary, and selects the owning parties whose stock will be used up to complete the required transaction.

Some transactions always consume consigned materials. These transactions include the following:

- Sales Order issues

- WIP issues

- Inter-organization transfers

- Miscellaneous issues

Other transactions can be set up to consume according to rules in the Consumption Transaction Setup window—located in Oracle Inventory. These transactions include Subinventory Transfers, Move Orders, Backflush Transfers, and others.

4. Consumption advice

Once the goods have been consumed, the quantities consumed should be communicated to the supplier to provide the necessary information for billing.

Nav: Reports >Consigned Inventory (when you click on this you see a window open for you).

Once you select all the parameters for example Supplier Item, item and Supplier and select go button. you will information below that page and you can drill down that information.This OA framework report it not written in regular Oracle reports.

The normal invoicing and payment cycles and cycle can take place once the supplier has sent the invoice, with the only difference being that invoices are matched to the consumption advice rather than the receipt.

Download the consignment demo from a buyer prospective @

http://www.forum4pmp.com/sites/default/files/consignment_buyer.swf

i want issues and their

i want issues and their solutions in distributions and manufacturing modules.

what are u faced recently issues in INV, OM, PO, BOM and WIP.

SEND ME ISSUES AND SOLUTIONS